🌍 Introduction: The Future of Sustainable Washing

🌍 Introduction: The Future of Sustainable Washing

Water is one of the most essential resources in garment washing processes — from desizing and bleaching to neutralization and softening. However, the global textile industry has long been criticized for its excessive water consumption. A single pair of jeans can require 70–100 liters of water during washing and finishing.

With growing awareness of environmental issues and rising production costs, washing factories are now turning towards Advanced Water Reduction Technologies — innovative systems that optimize water use, reduce waste, and ensure sustainability without sacrificing product quality.

This article explores every aspect of water-saving technology in garment washing factories — from mechanical innovations and chemical optimization to process automation and water recycling systems.

💧 1. Understanding Water Usage in Washing Factories

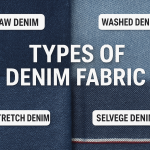

Garment washing involves multiple wet processes — such as desizing, enzyme wash, bleaching, neutralization, rinsing, tinting, and softening — each requiring substantial amounts of water.

📊 Average Water Consumption:

| Process | Water Used (Liters/kg fabric) |

|---|---|

| Desizing | 10–15 |

| Enzyme Wash | 15–20 |

| Bleach | 20–25 |

| Rinse (Multiple) | 25–30 |

| Softener | 10–15 |

Total: ~80–100 liters/kg fabric (traditional method)

This high water demand not only increases utility costs but also generates a large volume of wastewater that requires expensive treatment.

⚙️ 2. What is Water Reduction Technology?

Water Reduction Technology refers to a set of engineering, chemical, and operational innovations designed to minimize the use of fresh water in garment washing while maintaining process efficiency and quality.

These technologies focus on:

-

Recycling & Reusing process water

-

Reducing liquor ratios (water-to-fabric ratio)

-

Optimizing machine design

-

Smart dosing & monitoring systems

-

Chemical formulations that need less water

♻️ 3. Key Methods of Water Reduction

🔹 A. Low Liquor Ratio Machines

Modern washing machines are engineered with low liquor ratio technology (1:3 to 1:5) instead of traditional 1:8–1:12.

-

Benefit: Less water used per batch

-

Example: Jeanologia, Tonello, and Ramsons machines achieve up to 70% water savings.

-

Result: Reduced water, chemical, and energy costs.

🔹 B. Ozone Washing Technology

Ozone washing uses ozone gas (O₃) in place of water-heavy bleach processes.

-

How it Works: Ozone oxidizes indigo dye, achieving similar bleaching effects.

-

Benefits:

-

60–80% water reduction

-

No need for hot water (energy saving)

-

Shorter process time

-

Reduced chemical load

-

🔹 C. Laser Technology

Laser finishing replaces several water-based processes (like whisker, sandblast, and spray).

-

Advantages:

-

Zero water use

-

Safe for workers

-

Faster production

-

Consistent results

-

🔹 D. Water Recycling & Reuse System

This is one of the most impactful technologies in water reduction.

-

Process Steps:

-

Collection of wastewater from machines

-

Treatment through ETP (Effluent Treatment Plant) and RO (Reverse Osmosis)

-

Reuse of treated water in washing processes

-

-

Result: 50–80% reduction in fresh water consumption.

🔹 E. Smart Dosing & Automation Systems

Automation ensures precise control of water, chemical, and temperature.

-

Automatic dosing units measure and release exact amounts of chemical and water.

-

IoT-based monitoring systems track water usage in real time.

-

Result: Reduced waste and improved process consistency.

🔹 F. Enzyme & Chemical Optimization

Advanced chemicals are now formulated to work effectively with less water.

-

Single-bath enzymes can replace multiple processes.

-

Low-temperature bleaching agents reduce rinse requirements.

-

Eco-friendly detergents enhance water recyclability.

🧠 4. Process Optimization Techniques

🔸 Process Combination:

Combining Desize + Enzyme or Bleach + Neutralization in one bath saves both water and time.

🔸 Rinse Optimization:

Using counter-flow rinsing, where clean water enters at the last rinse stage and flows backward, can reduce rinse water up to 40%.

🔸 Mechanical Extraction:

High-speed hydro-extractors remove excess water from garments before drying — reducing drying time and energy use.

🏗️ 5. Infrastructure Improvements

🔹 Effluent Treatment Plant (ETP)

-

Treats wastewater for reuse or safe discharge.

-

Involves physical, chemical, and biological treatment stages.

-

Modern ETPs integrate membrane filtration, RO, and UV disinfection.

🔹 Rainwater Harvesting

Captures rainwater for use in washing or cooling systems, further cutting freshwater dependency.

🔹 Cooling & Condensate Recovery

Heat exchangers recover condensate water from steam dryers, reusing it for washing or heating.

🌿 6. Benefits of Implementing Water Reduction Technology

✅ Environmental Benefits:

-

Reduces freshwater withdrawal

-

Lowers wastewater discharge

-

Decreases pollution load in rivers

✅ Economic Benefits:

-

Lower utility and chemical costs

-

Reduced ETP load (saving treatment expenses)

-

Enhanced production efficiency

✅ Social & Compliance Benefits:

-

Meets Brand & Buyer sustainability standards (e.g., H&M, Levi’s, Inditex)

-

Improves corporate image

-

Enhances worker health & safety

📈 7. Case Studies: Real-World Implementations

👕 Example 1: Bangladesh Denim Factory

A leading washing plant in Bangladesh installed a recycling & ozone system.

-

Water usage reduced by 70%

-

Annual savings: 50 million liters

-

Achieved ZDHC Level 3 certification

👖 Example 2: Indian Sustainable Unit

By switching to low-liquor ratio machines and laser finishing,

-

Water savings reached 60%

-

Production time reduced by 25%

🧩 8. Challenges in Adoption

Despite the benefits, some challenges exist:

-

High initial investment cost

-

Need for skilled technical staff

-

Maintenance of advanced systems

-

Continuous monitoring of water quality

However, these are short-term barriers. Long-term savings and compliance benefits far outweigh them.

🚀 9. The Role of Digitalization (Industry 4.0)

With Industry 4.0 technologies, washing factories are becoming smarter:

-

IoT sensors monitor water flow and pressure in real-time

-

Data analytics identify waste patterns

-

AI-based predictive systems optimize water usage

-

Cloud dashboards allow managers to track savings factory-wide

Digital transformation ensures precision, transparency, and continuous improvement.

🌱 10. The Future of Sustainable Washing

The global garment industry is moving rapidly toward sustainability goals — with a focus on zero liquid discharge (ZLD) and closed-loop systems.

Future washing plants will operate with:

-

90–95% water recycling

-

Fully automated dosing systems

-

Renewable energy integration (solar-powered heating)

-

AI-driven monitoring for total efficiency

The goal is clear — produce fashion responsibly without draining the planet’s resources.

🏁 Conclusion

Advanced Water Reduction Technologies are revolutionizing the garment washing sector. By adopting innovative systems such as low-liquor ratio machines, ozone & laser technologies, and efficient water recycling, factories can achieve remarkable reductions in water consumption and operational costs.

For washing factories in Bangladesh and beyond, embracing these technologies isn’t just about compliance — it’s about building a sustainable future where business growth and environmental responsibility go hand in hand.