“Types of Denim Fabric: A Complete Guide for the Textile and Garment Industry”

Part 1: Introduction to Denim

What Is Denim?

Denim is one of the most iconic and versatile fabrics in the textile industry. It is a sturdy cotton twill weave fabric characterized by diagonal ribbing on the face of the cloth. Traditionally, the warp yarns are indigo-dyed, while the weft yarns remain white, giving denim its signature blue color with a lighter underside.

Denim is the heart of the jeans industry, but it extends far beyond that — into jackets, skirts, shirts, dresses, bags, upholstery, and even footwear. It represents a combination of durability, comfort, and timeless style.

Why Denim Is So Popular

The reason denim remains dominant for decades lies in its balance of function and fashion. It’s durable enough for industrial wear yet stylish enough for casual fashion. Moreover, with today’s innovations such as stretch denim, sustainable fibers, and eco-friendly finishes, denim has evolved to fit modern trends and environmental priorities.

Key characteristics that make denim special:

-

Durable and long-lasting

-

Ages beautifully — fades and wears uniquely with time

-

Versatile — suitable for garments, accessories, and home textiles

-

Comfortable — especially after washing and finishing

-

Fashionable — fits every generation and culture

A Brief History of Denim

Origins in France and Italy

The word denim originates from “Serge de Nîmes”, meaning “fabric from Nîmes” — a city in France. In the 17th century, French weavers developed a sturdy twill fabric used for workwear. Around the same period, Italian sailors from the city of Genoa also produced a similar cloth known as jean fabric — derived from Gênes, the French name for Genoa.

While jean fabric was made using cotton, wool, or linen blends, denim evolved into a cotton-based twill, setting the foundation for what we now recognize as blue jeans.

Denim in America

In the mid-19th century, Levi Strauss, a German immigrant in San Francisco, partnered with tailor Jacob Davis to create durable trousers for gold miners. In 1873, they patented riveted denim pants, marking the birth of modern jeans.

From rugged workwear to cultural symbol, denim became an expression of rebellion, youth, and individuality during the 1950s and 60s — thanks to Hollywood icons like James Dean and Marlon Brando. Today, denim remains a global fashion staple and a core material in the apparel industry.

Understanding Denim Fabric Construction

To truly understand different types of denim, it’s essential to know how it’s made. The fabric construction, yarn type, and finishing processes define its texture, strength, and final appearance.

1. Yarn Type and Fiber Composition

Originally, denim was 100% cotton. However, with technological advancement, manufacturers now use blends for better performance and comfort.

Common fiber compositions include:

-

100% Cotton Denim: Traditional, durable, breathable.

-

Cotton + Spandex (Stretch Denim): Provides elasticity and comfort.

-

Cotton + Polyester (Blended Denim): Adds strength and wrinkle resistance.

-

Cotton + Tencel/Lyocell: Enhances softness and sustainability.

-

Recycled Cotton or Polyester Denim: Reduces environmental impact.

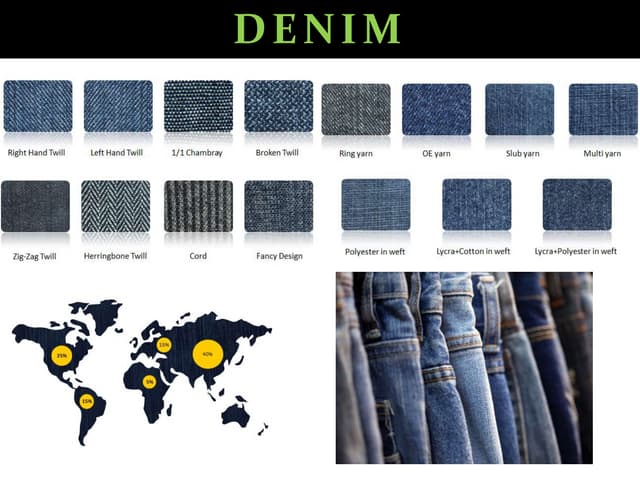

2. Twill Weave Structure

Denim is typically woven in a 3/1 right-hand twill structure. This means:

-

The warp yarn passes over three weft yarns, then under one.

-

Diagonal lines appear from bottom left to top right on the fabric face.

Some variations include:

-

Left-hand twill (LHT): Diagonal lines go from bottom right to top left — softer hand feel.

-

Right-hand twill (RHT): Classic denim twill, firm texture.

-

Broken twill: Zig-zag diagonal pattern that prevents twisting.

3. Indigo Dyeing Process

The deep blue color of denim comes from indigo dye, which has a unique surface dyeing property — it doesn’t penetrate deep into the fibers. This causes the faded look after wear or washing, one of denim’s most loved features.

There are several methods of dyeing denim yarns:

-

Rope Dyeing: High-quality method; yarns twisted into ropes and dipped in indigo multiple times for rich color.

-

Slasher Dyeing: Continuous dyeing process using sheet warps; faster and cost-effective.

-

Loop Dyeing: Similar to rope dyeing but done in loops for better efficiency.

4. Weight Classification

Denim fabrics are categorized by weight, measured in ounces per square yard:

| Type | Weight (oz/sq yd) | Common Use |

|---|---|---|

| Lightweight Denim | 4–8 oz | Shirts, summer dresses |

| Midweight Denim | 9–12 oz | Standard jeans, jackets |

| Heavyweight Denim | 13–16+ oz | Workwear, raw jeans, outerwear |

Heavier denim is more rigid and durable, while lighter weights offer comfort and breathability.

5. Selvedge vs. Non-Selvedge Denim

-

Selvedge Denim: Woven on traditional shuttle looms, producing clean, self-finished edges (no fraying). Known for high quality and premium appeal.

-

Non-Selvedge Denim: Made on modern projectile looms, wider fabric, cost-effective, commonly used in mass production.

Fabric Finishing and Washing

Raw denim straight from the loom is stiff and dark. To improve its hand feel and appearance, several finishing and washing processes are applied:

-

Sanforization: Pre-shrinking treatment to prevent size change during washing.

-

Desizing, Enzyme, and Stone Wash: Soften fabric, enhance texture.

-

Bleach and Tint Wash: Modify color and tone.

-

Laser or Ozone Finishing: Modern eco-friendly fading techniques.

These finishing processes not only improve comfort but also add character to the fabric, making every piece of denim unique.

Conclusion

In this first part, we explored the foundation of denim — its origin, construction, and why it remains a central fabric in fashion and industry alike. Understanding these basics sets the stage for the next sections, where we’ll dive into different types of denim fabrics in detail.

Major Types of Denim Fabrics — A Complete Overview

Denim is not a single fabric type — it’s a broad category encompassing a variety of constructions, finishes, and fiber combinations.

Each type of denim offers distinct properties that determine how it looks, feels, and performs in garments.

In this section, we’ll explore the main categories of denim fabric used in today’s textile and apparel industries, from traditional raw denim to innovative stretch and sustainable versions.

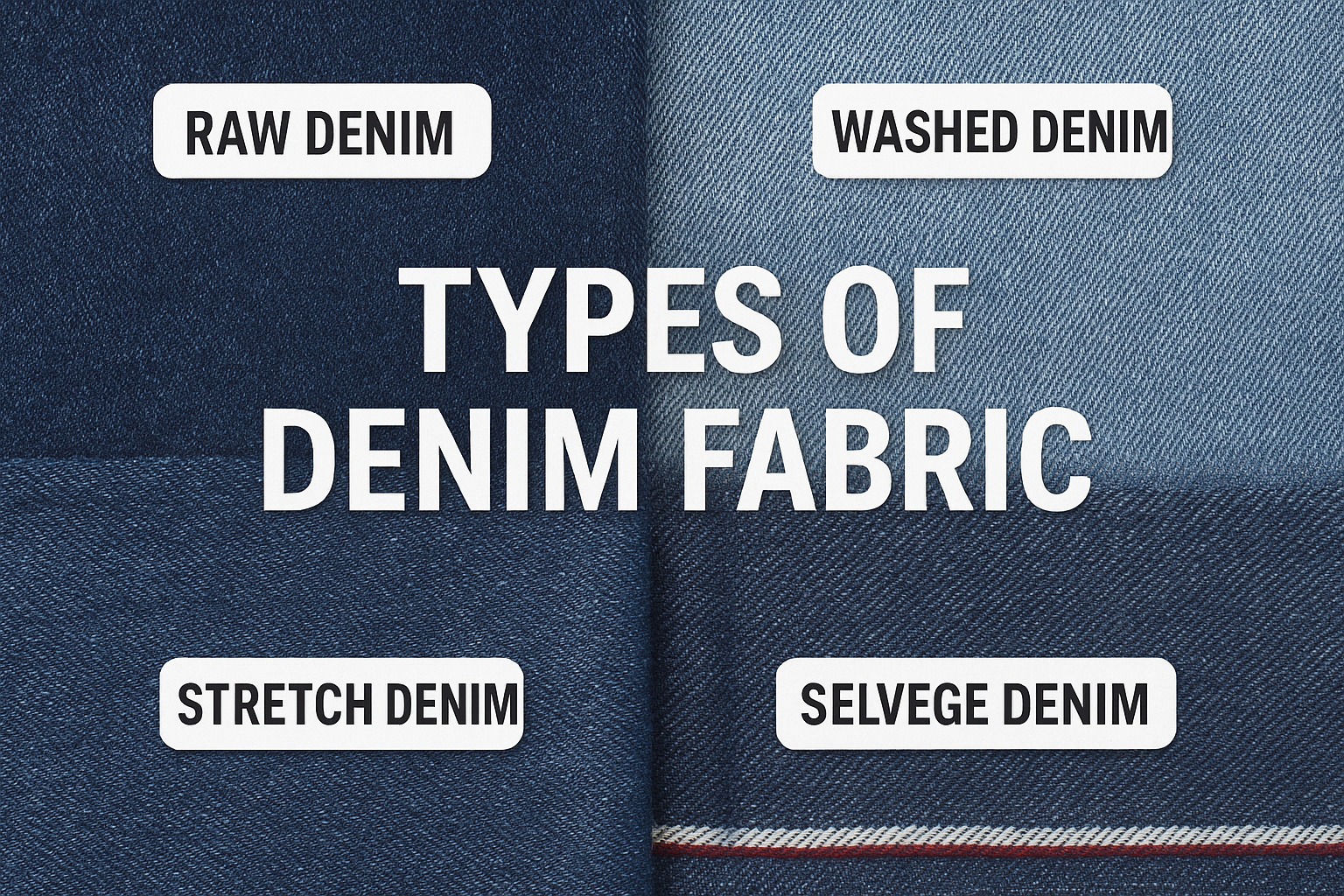

1. Raw Denim (Unwashed Denim)

Raw denim, also known as dry denim, is the purest and most traditional form of denim fabric. It comes straight off the loom and is not washed, sanded, or treated in any way after dyeing.

Key Characteristics

-

Stiff, dark, and rigid in feel

-

Deep indigo color

-

Shrinks slightly after the first wash (unless sanforized)

-

Develops unique fade patterns (whiskers, honeycombs) with wear

Applications

Raw denim is highly valued by denim enthusiasts and collectors who appreciate personalized aging — meaning the fade patterns form naturally based on body movement and lifestyle.

Commonly used for:

-

Premium jeans

-

Jackets

-

Workwear trousers

Advantages

-

Long-lasting and durable

-

Develops a custom look over time

-

Environmentally friendly (less washing and processing)

Disadvantages

-

Initially uncomfortable and rigid

-

Requires careful washing to maintain appearance

2. Washed Denim

Unlike raw denim, washed denim undergoes various washing treatments before being sold or sewn into garments. These washes reduce stiffness, shrinkage, and improve comfort.

Popular Washing Types

-

Rinse Wash: Light wash to remove excess dye and soften fabric

-

Stone Wash: Uses pumice stones to fade color and create vintage texture

-

Enzyme Wash: Uses enzymes to soften fabric in an eco-friendlier way than stones

-

Acid Wash / Bleach Wash: Creates sharp contrast patterns and high fading

-

Ozone or Laser Wash: Sustainable modern alternatives using minimal water

Applications

-

Casual jeans

-

Fashion apparel

-

Everyday wear

Advantages

-

Soft and comfortable from the start

-

Wide variety of looks

-

Reduces risk of shrinkage

Disadvantages

-

More resource-intensive (water, chemicals)

-

Color consistency can vary

3. Stretch Denim

Stretch denim is a revolutionary fabric innovation that changed the global jeans market. It combines cotton with elastane (spandex or Lycra) or other elastic fibers, giving the fabric flexibility and body-contouring comfort.

Composition

Typically:

-

98% cotton

-

2% elastane (can vary depending on desired stretch level)

Characteristics

-

Excellent elasticity and recovery

-

Soft, comfortable, and shape-retaining

-

Available in both lightweight and heavyweight versions

Applications

-

Skinny jeans

-

Jeggings

-

Women’s and children’s jeans

-

Fashion denim jackets and dresses

Advantages

-

High comfort level and freedom of movement

-

Keeps shape after repeated wear

-

Enhances fit and style versatility

Disadvantages

-

May lose elasticity over time if low-quality spandex is used

-

Slightly less durable than rigid denim

4. Selvedge Denim

Selvedge (or selvage) denim refers to denim woven on traditional shuttle looms, which produce a narrow, tightly woven edge that prevents unraveling.

The term “selvedge” comes from “self-edge.”

Characteristics

-

Clean, finished edge (often with red or white thread)

-

Dense, tightly woven texture

-

Typically heavier weight

-

Recognized for high craftsmanship

Why It’s Premium

Selvedge denim looms operate slower, producing less fabric but with higher density and character. The result is a high-quality, durable, and collectible denim often favored by enthusiasts.

Applications

-

Premium jeans

-

Heritage workwear

-

Limited-edition denim garments

Advantages

-

Superior strength and durability

-

Beautiful fade potential

-

Symbol of authentic craftsmanship

Disadvantages

-

More expensive due to slow production

-

Narrow fabric width (higher garment production cost)

5. Stretch Selvedge Denim

A modern innovation combining traditional selvedge weaving with stretch yarns.

It offers the best of both worlds: authentic look and feel with improved flexibility.

Composition

-

Cotton + Elastane

-

Produced on shuttle looms

Applications

-

Premium stretch jeans

-

Tailored denim apparel

Advantages

-

Retains authentic selvedge quality

-

Comfortable fit

-

Ideal for premium fashion markets

6. Poly-Cotton Denim

Poly-cotton denim blends cotton with polyester fibers, improving strength, wrinkle resistance, and dimensional stability.

Characteristics

-

Softer drape and smoother texture

-

More resistant to shrinkage and creasing

-

Color lasts longer due to polyester stability

Applications

-

Workwear

-

Uniforms

-

Everyday jeans

Advantages

-

Durable and easy to maintain

-

Quick drying

-

Affordable

Disadvantages

-

Less breathable than 100% cotton

-

Not preferred for high-end fashion jeans

7. Organic Denim

With sustainability becoming a major focus, organic denim is gaining traction.

It is made using organic cotton — grown without pesticides, synthetic fertilizers, or GMOs — and dyed using eco-friendly indigo processes.

Characteristics

-

Soft and skin-friendly

-

Reduced environmental footprint

-

Often combined with sustainable washing (ozone, laser, enzyme)

Applications

-

Sustainable fashion brands

-

Eco-conscious jeans and shirts

Advantages

-

Environmentally friendly

-

Promotes ethical production

-

Increasing consumer demand

Disadvantages

-

Higher cost

-

Limited global production capacity

8. Recycled Denim

Recycled denim uses post-consumer denim waste or industrial cutting waste to produce new fabric.

This aligns with the circular fashion and zero-waste manufacturing concepts.

Manufacturing Process

-

Old jeans are collected.

-

Fabrics are shredded into fibers.

-

Re-spun into yarns (sometimes blended with virgin cotton or polyester).

-

Woven and finished like new denim.

Applications

-

Sustainable jeans

-

Accessories and bags

-

Home textiles

Advantages

-

Reduces textile waste

-

Saves water and energy

-

Promotes circular economy

Disadvantages

-

Slightly lower tensile strength

-

Limited shade consistency

9. Ecru Denim

Ecru denim is the un-dyed version of denim fabric. Instead of indigo-dyed warp yarns, it uses natural-colored yarns (off-white or cream), maintaining the raw cotton look.

Characteristics

-

Natural, neutral tone

-

Minimal chemical usage

-

Often soft and breathable

Applications

-

Summer wear

-

Fashion apparel

-

Minimalist designs

Advantages

-

Environmentally friendly

-

Versatile for dyeing or printing

Disadvantages

-

Gets dirty easily

-

Lacks classic “blue denim” identity

10. Coated Denim

Coated denim involves applying a thin surface layer of resin, wax, or polyurethane to achieve a leather-like or glossy finish.

Characteristics

-

Sleek and shiny appearance

-

Water-resistant

-

Slightly stiffer hand feel

Applications

-

Fashion jeans

-

Jackets

-

Streetwear and premium fashion lines

Advantages

-

Modern, edgy look

-

Protects against moisture

-

Enhances texture and color depth

Disadvantages

-

Reduced breathability

-

May crack or peel with heavy washing

11. Colored Denim

Though blue remains iconic, denim today comes in many colors — black, grey, red, green, or even pastel tones.

This is achieved by using sulfur dyes instead of indigo or by over-dyeing post-washed denim.

Applications

-

Trend-driven fashion

-

Uniforms

-

Children’s apparel

Advantages

-

Wide design flexibility

-

Fade-resistant shades

Disadvantages

-

Some sulfur dyes may cause skin irritation if not properly fixed

12. Marble & Acid Wash Denim

Acid-wash or marble denim is achieved using chlorine-soaked pumice stones that create high-contrast, random fading patterns.

Characteristics

-

Distinctive marbled appearance

-

Soft and worn-in feel

-

Lightweight to medium weight

Applications

-

Vintage-style jeans and jackets

-

Streetwear collections

Advantages

-

Unique patterns on every garment

-

Popular in retro fashion

Disadvantages

-

High chemical usage

-

May weaken fabric fibers

Summary Comparison Table

| Type of Denim | Key Feature | Primary Use | Main Advantage | Drawback |

|---|---|---|---|---|

| Raw Denim | Unwashed, rigid | Premium jeans | Personalized fades | Initially stiff |

| Washed Denim | Pre-treated | Casual wear | Soft & comfortable | Resource intensive |

| Stretch Denim | Contains elastane | Skinny jeans | Flexible fit | May lose stretch |

| Selvedge Denim | Woven on shuttle looms | Premium jeans | Durable & authentic | Expensive |

| Poly-Cotton Denim | Cotton + polyester | Workwear | Strong & easy-care | Less breathable |

| Organic Denim | Eco-friendly cotton | Sustainable fashion | Green production | Costly |

| Recycled Denim | From waste fibers | Eco-products | Waste reduction | Slightly weaker |

| Ecru Denim | Un-dyed | Minimalist apparel | Natural look | Dirt-prone |

| Coated Denim | Surface finish | Jackets & streetwear | Stylish & water-resistant | Can peel |

| Colored Denim | Sulfur or pigment dyes | Fashion & uniforms | Design flexibility | Possible irritation |

Conclusion

From rugged raw denim to sleek coated finishes, and from traditional selvedge to modern sustainable fabrics, denim’s versatility is endless.

Each type offers unique properties that serve different design needs, industries, and sustainability goals.

In the next section, we’ll move deeper into specialized and innovative denim types — exploring high-performance, eco-conscious, and technical denim fabrics shaping the future of the industry.

Specialized and Innovative Denims — Exploring Modern Developments in Denim Fabric

As fashion, technology, and sustainability evolve, denim has expanded beyond traditional styles. The modern denim industry is defined by innovation, comfort, and eco-conscious design — combining advanced fiber technologies, creative textures, and smarter production systems.

In this section, we’ll explore specialized denim varieties and the technological innovations transforming this legendary fabric.

1. Slub Denim

Slub denim is characterized by irregular yarn thickness, creating a textured and uneven surface. These yarns are intentionally engineered with variations in diameter, giving the denim a unique, vintage look.

Characteristics

-

Visible irregular “slubs” or streaks

-

Natural, handcrafted appearance

-

Slight variations in shade due to yarn thickness

Applications

-

Vintage jeans

-

Streetwear

-

Jackets and casual wear

Advantages

-

Unique, natural aesthetic

-

Enhances depth and visual character

-

Excellent for distressed and faded looks

Disadvantages

-

May appear inconsistent in mass production

-

Slightly less uniform dye absorption

2. Crushed Denim

Crushed denim has a permanently wrinkled or creased surface, achieved through mechanical and chemical finishing processes. This creates a three-dimensional texture that adds style and softness.

Characteristics

-

Wrinkled surface texture

-

Soft and supple hand feel

-

Usually pre-washed and softened

Applications

-

Fashion jeans

-

Jackets and skirts

-

Children’s wear

Advantages

-

Distinctive aesthetic

-

Comfortable to wear

-

No need for ironing

Disadvantages

-

Complex production process

-

May lose wrinkles over time if not stabilized

3. Bull Denim

Bull denim is a heavyweight, tightly woven 3×1 twill fabric that is typically dyed after weaving instead of before. It is extremely durable and has a matte appearance.

Characteristics

-

Heavier weight (13–16 oz or more)

-

No indigo dye; piece-dyed in solid colors

-

High durability and strength

Applications

-

Upholstery and bags

-

Heavy-duty workwear

-

Jackets and trousers

Advantages

-

Long-lasting and abrasion-resistant

-

Excellent color depth and coverage

Disadvantages

-

Stiffer and less breathable

-

Limited flexibility compared to stretch denim

4. Reverse Denim

Reverse denim simply refers to using the back side of the denim fabric as the face. The back side, typically lighter and smoother, gives garments a unique tonal variation.

Characteristics

-

Light blue or white weft appearance

-

Soft and less textured

-

Often used for design contrast

Applications

-

Jackets and shirts

-

Contrast panel jeans

-

Designer apparel

Advantages

-

Creates stylish contrast

-

Softer surface against the skin

Disadvantages

-

May not have classic denim fading pattern

5. Mercerized Denim

Mercerization is a chemical treatment using caustic soda (NaOH) that gives cotton fibers a silky luster, higher strength, and improved dye uptake.

Characteristics

-

Bright, lustrous surface

-

Smoother and stronger fabric

-

Enhanced color brilliance

Applications

-

Premium jeans

-

Fashion shirts

-

Designer denim garments

Advantages

-

Stronger and more colorfast

-

Soft, glossy finish

Disadvantages

-

Increases cost of production

-

Not suitable for rugged, raw styles

6. Laminated Denim

Laminated denim is made by bonding a layer of plastic film, foam, or membrane onto the denim surface, enhancing functionality and aesthetics.

Characteristics

-

Glossy, rubberized, or metallic finish

-

Water-resistant and windproof

-

Adds weight and stiffness

Applications

-

Outerwear

-

Fashion-forward jackets

-

Performance wear

Advantages

-

Excellent protection from wind and moisture

-

Eye-catching visual effects

Disadvantages

-

Limited breathability

-

Can delaminate over time if poorly manufactured

7. Coated and Resin-Treated Denim

This fabric type involves applying polyurethane or acrylic resins to the denim surface, resulting in a leather-like appearance.

Different coating techniques create glossy, matte, or cracked textures.

Characteristics

-

Sleek, edgy look

-

Enhanced durability and water resistance

-

Slight stiffness

Applications

-

Biker jeans

-

Jackets

-

Fashion garments

Advantages

-

Strong and stylish

-

Water- and stain-resistant

Disadvantages

-

Reduced air permeability

-

Can feel less natural on skin

8. Brushed Denim

Brushed denim undergoes a mechanical brushing process that raises the fabric’s surface fibers, producing a soft, velvety touch similar to flannel.

Characteristics

-

Fuzzy, warm surface

-

Lightweight to midweight fabric

-

Excellent comfort

Applications

-

Winterwear

-

Casual shirts

-

Children’s jeans

Advantages

-

Soft, cozy texture

-

Retains warmth

Disadvantages

-

Slightly lower abrasion resistance

9. Crinkle & Wrinkle Denim

These fabrics are treated with heat-setting and chemical techniques to create permanent creases, adding depth and visual interest.

Applications

-

Designer jeans

-

Modern fashion lines

Advantages

-

Stylish, lived-in appearance

-

Reduces ironing needs

Disadvantages

-

Specialized finishing increases cost

10. Ice Wash & Snow Wash Denim

These washing techniques use pumice stones and bleaching agents to produce a frosted, pale-blue effect.

Characteristics

-

Light, frosty tone

-

High-contrast surface appearance

Applications

-

Vintage-style jeans and jackets

Advantages

-

Unique retro look

-

Soft hand feel

Disadvantages

-

High water and chemical usage

11. Sustainable and Eco-Friendly Denim

Sustainability is now at the heart of modern textile innovation. Denim manufacturing has evolved to reduce water, energy, and chemical consumption, while improving worker and environmental safety.

Key Sustainable Approaches

a. Organic Cotton Denim

Produced from cotton grown without pesticides or synthetic fertilizers, conserving soil health and biodiversity.

b. Recycled Denim

Uses pre- or post-consumer denim waste to create new yarns and fabrics, reducing landfill waste.

c. Waterless Dyeing

New technologies such as foam dyeing and indigo dyeing without water cut water usage by up to 90%.

d. Laser Finishing

Lasers replace sandblasting and hand scraping, achieving faded looks without harmful chemicals.

e. Ozone & Enzyme Washes

Natural gases and enzymes are used to fade and soften denim sustainably.

f. Bio-based and Plant-Derived Fibers

Use of hemp, bamboo, and lyocell (Tencel) fibers to improve biodegradability and reduce cotton dependency.

Advantages

-

Reduced environmental footprint

-

Improved worker safety

-

Meets global sustainability certifications (GOTS, OEKO-TEX, BCI, etc.)

Disadvantages

-

Higher production cost

-

Technology access limited in developing regions

12. Smart and Functional Denim

The new era of denim is technologically enhanced. “Smart denim” integrates nanotechnology, phase-change materials, or conductive fibers for added functionality.

Examples

-

Moisture-Wicking Denim: Transfers sweat away from skin for activewear.

-

Anti-bacterial Denim: Uses silver nanoparticles or natural treatments like aloe vera or bamboo charcoal.

-

UV-Protective Denim: Blocks harmful ultraviolet rays.

-

Temperature-Regulating Denim: Adapts to body temperature changes using microcapsule technology.

-

Conductive Denim: Used in smart garments with sensors or wearable electronics.

Applications

-

Sportswear

-

Military and outdoor apparel

-

Future-ready fashion garments

Advantages

-

High-performance properties

-

Expands denim’s application scope

Disadvantages

-

Expensive production process

-

Complex recycling

13. Laser & Ozone-Processed Denim

Modern denim finishing relies heavily on laser engraving and ozone fading to replace hazardous traditional techniques.

Laser Finishing

Uses laser beams to etch patterns, fades, and whiskers onto denim fabric.

-

Advantages: Precise, clean, no water required, reproducible results.

-

Applications: Fashion jeans, logos, distress effects.

Ozone Finishing

Uses ozone gas to bleach and fade denim without water.

-

Advantages: Eco-friendly, eliminates harsh chemicals, saves time and energy.

-

Applications: Sustainable denim production lines.

These methods are key to modern eco-denim factories pursuing sustainability and efficiency.

14. Waterless & Eco-Dyeing Technologies

Traditional indigo dyeing consumes enormous water volumes. Today, innovative dyeing systems are reducing this dramatically:

-

Foam Dyeing (Dry Indigo): Uses foam instead of liquid baths, reducing water by 90%.

-

Electrochemical Dyeing: Uses electricity to bond indigo molecules directly onto fibers.

-

Cold Pad Batch (CPB): Reduces heat energy consumption.

Such technologies mark the shift toward a circular, sustainable denim ecosystem.

15. Reversible Denim

Reversible denim allows garments to be worn inside-out — offering two styles in one piece.

One side might feature classic blue twill, while the other displays lighter or printed patterns.

Applications

-

Fashion jeans

-

Jackets and shorts

Advantages

-

Dual functionality

-

Space-saving and creative

Disadvantages

-

Higher manufacturing cost

-

Slightly thicker fabric feel

16. Stretchable Hybrid Denim (Bi-Stretch and 4-Way Stretch)

Unlike traditional stretch denim (which stretches only weft-wise), hybrid stretch fabrics stretch in both warp and weft directions.

Characteristics

-

Enhanced flexibility

-

High shape recovery

-

Ideal for slim fits and activewear

Applications

-

Skinny jeans

-

Jeggings

-

Performance denim apparel

Advantages

-

Superior comfort and movement freedom

-

Ideal for women’s and athletic denim

Disadvantages

-

More expensive yarn and weaving setup

17. Laser-Printed and Patterned Denim

Modern fashion integrates digital printing and laser design onto denim surfaces — creating detailed textures, logos, and patterns without fabric damage.

Applications

-

Designer denim

-

Limited edition fashion lines

Advantages

-

Customization potential

-

Low chemical waste

Disadvantages

-

Requires advanced machinery and trained staff

Conclusion

From slub and bull denim to smart and sustainable innovations, the denim world is more diverse and technologically advanced than ever. These specialized types show how denim continues to evolve — blending tradition, performance, and sustainability.

In the final section, we’ll focus on real-world applications, care methods, and the future direction of denim in fashion and industry.

Applications, Care, and Future Trends of Denim Fabric

Denim is not just a fabric — it’s a global lifestyle material. From rugged workwear to high-fashion runways, its adaptability has made it a symbol of durability, comfort, and timeless appeal. In this final part, we’ll explore how denim is used across industries, how to care for it properly, and what the future holds for this ever-evolving textile.

1. Applications of Denim Fabric

Denim’s usage extends far beyond jeans. Today, it’s a multifunctional material used in apparel, accessories, interiors, and industrial products. Its combination of strength, comfort, and style makes it indispensable across markets.

1.1 Apparel Industry

Denim’s primary application remains in apparel, accounting for over 70% of total global denim consumption.

a. Jeans

The most iconic denim product, jeans are produced in countless fits and finishes:

-

Straight, slim, bootcut, and relaxed fits

-

Raw, washed, or distressed

-

Classic blue, black, and colored versions

b. Jackets and Shirts

Denim jackets are timeless outerwear garments, often unisex.

Denim shirts combine a rugged look with modern style versatility.

c. Dresses, Skirts, and Shorts

Lightweight denim and chambray are used in summer dresses and skirts, providing breathability with structure.

d. Overalls and Jumpsuits

A heritage workwear item now revived as a fashion trend — functional and comfortable.

e. Streetwear and Athleisure

Stretch and coated denims are used in joggers, hoodies, and hybrid performance garments.

1.2 Accessories and Footwear

Denim’s adaptability allows it to cross into lifestyle and accessories markets.

Common Uses:

-

Bags & Backpacks: Durable and fashionable

-

Caps & Hats: Lightweight denims for casualwear

-

Shoes & Sneakers: Used as upper material for comfort and aesthetics

-

Belts & Wallets: Thick denim reinforced with leather

Denim accessories appeal to both traditional and youth markets due to their casual elegance and durability.

1.3 Home Textiles and Interiors

Denim’s toughness and rich texture have made it a favorite for home applications:

-

Cushion covers, upholstery, bean bags

-

Curtains, table runners, and quilts

Interior designers use recycled or raw denim for a modern, rustic look, blending sustainability with comfort.

1.4 Industrial and Technical Applications

Heavyweight and blended denims are used in:

-

Workwear uniforms (construction, mechanics)

-

Protective clothing (fire-retardant or cut-resistant denim)

-

Industrial filters and upholstery

Advanced technical finishes, like flame-retardant and anti-static coatings, have expanded denim’s role beyond fashion into functional apparel.

2. Denim Care and Maintenance

Proper care extends the life of denim garments and preserves their texture and appearance. Since denim is often indigo-dyed, washing and maintenance play a vital role in maintaining color and comfort.

2.1 Washing Guidelines

a. Raw Denim

-

Avoid frequent washing for the first 6 months.

-

Spot-clean stains with mild detergent.

-

When washing is needed, turn inside out and use cold water.

-

Air-dry in shade to maintain shape and color.

b. Washed or Pre-Shrunk Denim

-

Wash separately to avoid dye transfer.

-

Use mild, liquid detergents (avoid bleach).

-

Wash inside out in cold or lukewarm water.

-

Avoid tumble drying; instead, hang dry naturally.

c. Stretch Denim

-

Avoid hot water and high heat — it damages elastane fibers.

-

Wash gently and air-dry flat.

2.2 Ironing and Storage

-

Use medium heat (cotton setting) for ironing.

-

Iron inside out to protect surface texture.

-

Store folded in cool, dry places to prevent mildew.

2.3 Eco-Friendly Denim Care Tips

-

Wash less frequently to save water and energy.

-

Use eco-friendly detergents.

-

Line dry instead of machine drying.

-

Donate or recycle old denim through textile recycling programs.

3. Sustainability in Denim Production

Sustainability is no longer optional — it’s an essential pillar of modern denim manufacturing. The global denim industry is rapidly embracing eco-friendly practices across fiber sourcing, dyeing, washing, and finishing.

3.1 Sustainable Fiber Choices

-

Organic Cotton: Reduces pesticide and fertilizer usage.

-

Recycled Fibers: Upcycled from waste denim.

-

Hemp and Tencel: Renewable fibers that reduce water use.

-

Bio-based Stretch Fibers: Replacing petroleum-based elastane.

3.2 Sustainable Dyeing & Finishing

Innovations such as:

-

Indigo dyeing without water (Foam dyeing)

-

Laser finishing replacing sandblasting

-

Ozone washing reducing chemical load

-

Enzyme treatments instead of stones or bleach

These steps drastically lower water and energy consumption while maintaining desired fashion effects.

3.3 Certifications and Standards

Eco-denim producers often follow international standards:

-

GOTS (Global Organic Textile Standard)

-

OEKO-TEX Standard 100

-

Better Cotton Initiative (BCI)

-

Cradle to Cradle Certified™

Such certifications ensure traceability, worker safety, and environmental compliance.

4. Future Trends in Denim Fabric

The future of denim is being shaped by technology, sustainability, and customization. Let’s explore the most promising directions shaping tomorrow’s denim industry.

4.1 Smart Denim Technology

Denim is merging with smart textiles through sensor-embedded fabrics and wearable electronics.

Examples include:

-

Jeans that track body movement or posture

-

Jackets with built-in Bluetooth controls

-

Conductive fibers for touch-sensitive surfaces

Brands like Google & Levi’s (Project Jacquard) have already launched such products, showing the potential of connected denim.

4.2 Digitalization and On-Demand Manufacturing

Modern factories use AI-driven design software and 3D virtual sampling to reduce waste and improve speed.

With on-demand denim production, brands can manufacture only what is needed — minimizing overproduction.

Key innovations:

-

3D virtual fit modeling

-

Automated laser finishing

-

AI-based wash simulation

This trend leads toward mass customization — personalized jeans made to order.

4.3 Circular Denim Economy

The denim industry is transitioning toward a circular model, emphasizing reuse, recycling, and repair.

Future denim will be designed for disassembly and recyclability — using mono-materials and biodegradable trims.

Circular Actions Include:

-

Take-back programs for old jeans

-

Mechanical and chemical fiber recycling

-

Regenerative cotton farming

-

Compostable stretch yarns

Such innovations make denim both eco-responsible and resource-efficient.

4.4 Minimal-Water and Chemical-Free Production

With water scarcity becoming a global concern, denim producers are investing in zero-liquid discharge (ZLD) systems and waterless dyeing technologies.

-

Foam dyeing and electrochemical indigo minimize effluent discharge.

-

Natural indigo and plant-based dyes are replacing synthetics.

-

Nano-bubble washing reduces both water and chemicals.

Factories adopting these methods can reduce their environmental footprint by up to 85%.

4.5 Sustainable Fashion Collaborations

Major brands and textile innovators are collaborating to create greener denim:

-

Levi’s x Renewcell: Producing jeans from 100% recycled cellulose fibers.

-

Wrangler’s Indigood™: Foam dyeing innovation for zero water use.

-

H&M Conscious Denim: Combining recycled cotton and eco-wash technologies.

-

G-Star Raw’s Cradle to Cradle Gold Collection: Fully biodegradable jeans.

These partnerships represent the global movement toward responsible denim fashion.

4.6 Consumer Awareness and Transparency

Modern consumers demand traceability and ethical sourcing. Blockchain and digital labeling are emerging as tools to track denim’s entire lifecycle — from cotton farm to final product.

This transparency builds trust and encourages responsible consumption, essential for sustainable growth in the apparel industry.

5. Denim’s Cultural and Economic Impact

Beyond technology, denim continues to play a massive role in culture, economy, and global trade.

-

The global denim market is valued at over $60 billion USD, with steady annual growth.

-

Denim symbolizes freedom, individuality, and equality, transcending age, gender, and culture.

-

It has become an art canvas — seen in murals, exhibitions, and couture collections.

From factory floors to high fashion runways, denim represents both heritage and innovation.

6. Summary: The Evolution of Denim

| Era | Key Development | Impact |

|---|---|---|

| 1800s | Workwear origins | Durable, utilitarian use |

| 1950s | Hollywood influence | Symbol of youth rebellion |

| 1970s–90s | Fashion explosion | Global casualwear staple |

| 2000s | Stretch & designer denim | Comfort and style fusion |

| 2010s | Sustainable denim | Eco-conscious production |

| 2020s & beyond | Smart & circular denim | Technological and sustainable future |

7. Conclusion

Denim has traveled an extraordinary journey — from miners’ uniforms to runway fashion, from rigid cotton twill to smart, sustainable textiles. Its continued relevance lies in its ability to adapt, innovate, and inspire.

For the textile and garment industry, denim represents:

-

A bridge between tradition and technology

-

A platform for sustainable transformation

-

A material that unites craftsmanship with modern design

As we move toward a circular, digital, and eco-conscious future, denim will remain an enduring symbol of both style and responsibility — proving once again why it’s called the fabric that never fades.