In the world of fashion and textiles, garment washing stands as one of the most transformative processes that bridge the gap between raw production and the polished perfection of the final product. What may seem like a simple rinse is, in reality, a delicate dance between chemistry, artistry, and innovation — a process that defines not only the texture and appearance of garments but also their comfort, character, and identity. “Beyond the Rinse” explores the fascinating art and science of garment washing — from its historical roots to modern-day innovations shaping the global apparel industry.

The Origin: From Basic Clean to Creative Expression

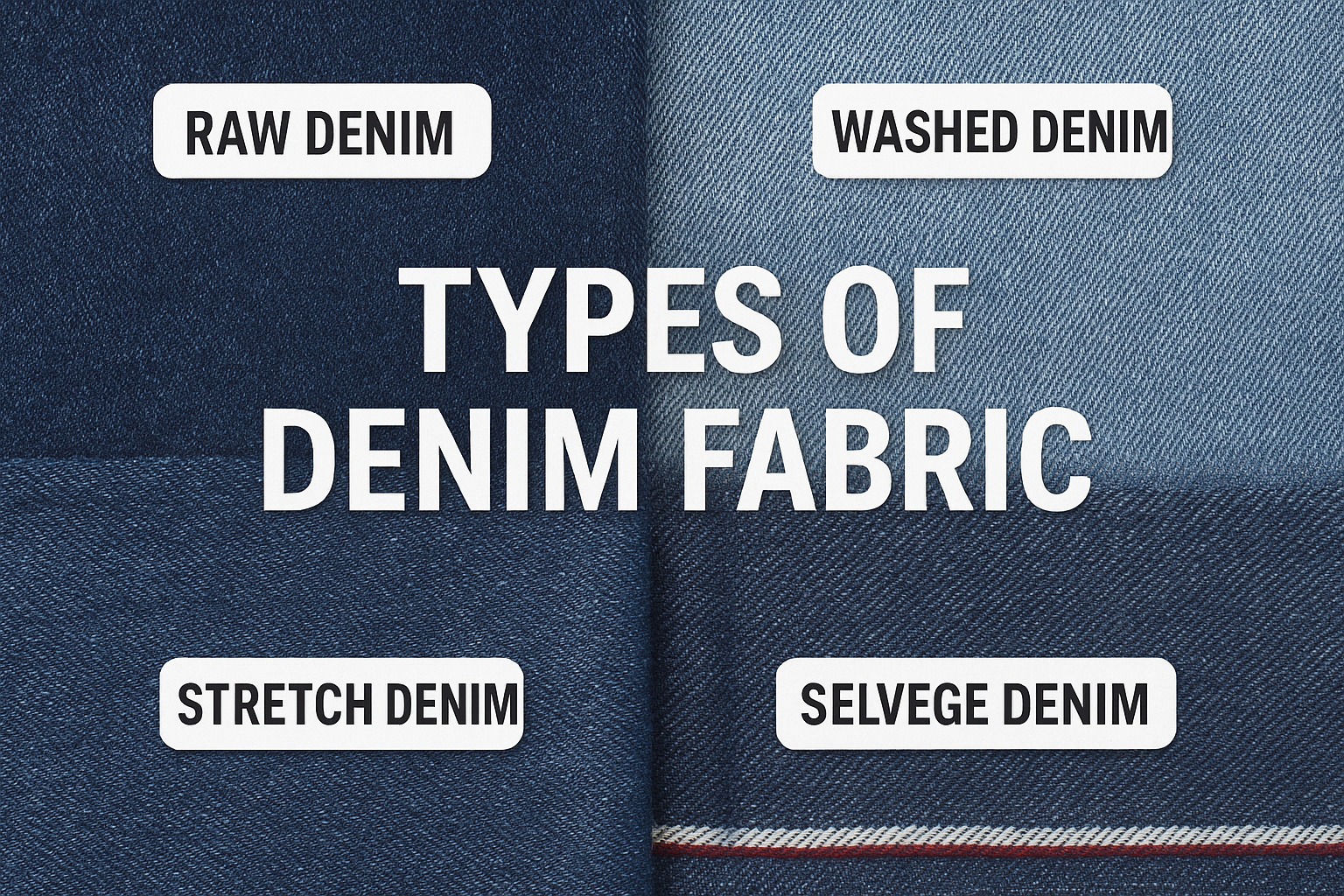

Garment washing was once merely a post-production step meant to clean garments before shipment. However, as fashion evolved, washing became an art form — an integral part of achieving the desired “look and feel” that distinguishes one brand from another. The denim revolution of the 1970s and 1980s, for instance, turned garment washing into a creative powerhouse. Stone washing, enzyme washing, and acid washing emerged not just as techniques but as expressions of individuality and rebellion.

Today, garment washing goes far beyond removing impurities. It defines trends, adds softness, ensures shrinkage control, enhances color tone, and even contributes to sustainability when done responsibly. From luxury fashion houses to mass-market brands, washing techniques have become synonymous with brand identity and consumer preference.

Understanding the Science: Fabric Meets Chemistry

At its core, garment washing is a scientific process that combines water, mechanical action, time, temperature, and chemical agents to achieve a specific result. Each fabric — cotton, denim, polyester, or blends — reacts differently based on its fiber composition and weave structure. Understanding these reactions is the foundation of every successful wash.

1. Mechanical Action:

This refers to the movement of garments inside industrial washing machines or tumblers. Mechanical friction helps in removing surface fibers, loosening dye, and creating a desired worn-in effect. Too much agitation, however, can damage delicate fibers, leading to holes or uneven textures.

2. Temperature Control:

Temperature plays a key role in how chemicals and enzymes interact with fabrics. For example, enzymes used in bio-washing require specific temperature ranges (usually between 40°C and 60°C) to activate and break down cellulose fibers effectively. High temperatures can intensify color fading, while low temperatures may result in incomplete reactions.

3. Chemical Components:

Chemicals are the invisible artists behind the scenes — from detergents and softeners to bleaching agents and enzymes. Each serves a distinct purpose.

- Detergents remove impurities and oils.

- Softeners improve fabric hand-feel and drape.

- Bleaching agents (like sodium hypochlorite or hydrogen peroxide) lighten shades or create contrast effects.

- Enzymes (like cellulase or amylase) work biologically to remove surface fuzz, resulting in smoother, softer textures.

Balancing these components requires both scientific expertise and artistic intuition — too much chemical can destroy fabric integrity, while too little may not achieve the desired visual or tactile effect.

The Artistic Side: Crafting Identity Through Wash Effects

While science ensures precision, art brings emotion and character into the process. The artistry of garment washing lies in the subtle variations — the faded edges, the vintage tints, the hand-scraped textures — that tell stories of craftsmanship and individuality.

Here are some of the most iconic wash effects that have defined the fashion landscape:

1. Stone Wash:

One of the earliest and most famous techniques, stone washing uses pumice stones in the washing process. The friction between stones and fabric creates a rugged, worn-out look with lighter patches. Though visually appealing, traditional stone washing can be harsh on machines and the environment, leading to newer alternatives like synthetic stones and enzyme-based replacements.

2. Enzyme Wash:

A sustainable evolution of stone washing, enzyme washing uses natural enzymes to break down cellulose fibers on the garment surface. This not only softens the fabric but also gives a cleaner, more uniform appearance. It’s a popular choice for denim and cotton garments aiming for a premium finish.

3. Acid Wash:

Famous during the 1980s punk era, acid wash involves treating denim with chlorine or potassium permanganate to create dramatic contrast effects. Today, safer and more controlled methods like ozone or laser treatments are replacing chemical-intensive acid washes.

4. Sand Blasting and Hand Scraping:

These manual or semi-automated processes mimic natural wear and tear on jeans, adding personality to each piece. Skilled artisans strategically scrape or blast sand in specific areas — knees, thighs, or pockets — to simulate a lived-in look.

5. Pigment and Garment Dye Washes:

These techniques add vibrant color variations and vintage effects. Unlike fabric dyeing, garment dyeing happens after stitching, allowing color penetration that highlights seams and stitching details.

The artistry lies not just in applying these methods but in controlling them precisely to create consistency across production — a challenge that blends human skill with machine precision.

Innovation and Technology: Redefining the Future of Washing

Modern garment washing has evolved from water-heavy, chemical-driven operations to highly engineered, sustainable systems. The industry now focuses on reducing environmental impact while enhancing creative flexibility.

1. Ozone Washing:

Ozone technology uses oxygen gas to fade and disinfect garments without water or harsh chemicals. It significantly reduces water usage and energy costs while providing a naturally faded look.

2. Laser Finishing:

Laser technology allows brands to replicate intricate wash patterns digitally. Instead of manual abrasion or chemicals, lasers etch designs directly onto the fabric surface. This precision-driven method enhances consistency and safety.

3. E-flow and Nano Bubble Technology:

These systems use microscopic bubbles or air flow to distribute chemicals evenly with minimal water. The result? Up to 90% water savings and reduced chemical consumption — a leap forward in sustainable manufacturing.

4. Enzyme Engineering:

Advances in biotechnology have led to the development of customized enzymes that work efficiently at lower temperatures and shorter cycle times, reducing both energy use and carbon footprint.

Sustainability is no longer an optional feature but a defining benchmark of excellence. Consumers now value eco-friendly production as much as style and comfort. The brands investing in green washing technologies are leading the new frontier of responsible fashion.

Quality Control: Balancing Art, Science, and Consistency

Behind every beautifully washed garment is a team of experts ensuring that quality, safety, and compliance meet industry standards. Garment washing involves numerous quality parameters that must be monitored:

- Shrinkage Control: Ensures that garments retain their size and shape after washing.

- Color Fastness: Measures how well a fabric retains its dye when exposed to washing, rubbing, or sunlight.

- Fabric Strength: Ensures the washing process doesn’t weaken the fabric structure.

- Softness and Hand Feel: Assesses tactile quality — crucial for consumer satisfaction.

A perfect wash is one where the garment not only looks appealing but also performs well in durability and comfort.

The Human Element: Skill and Experience

Despite automation, garment washing remains a human-driven art. Wash technicians, lab assistants, and quality controllers rely on experience and intuition to balance formulas, adjust machine settings, and predict outcomes. A skilled washer can “read” the garment — understanding how small changes in time, temperature, or chemical mix can alter the final look dramatically.

This blend of hands-on expertise and scientific precision makes garment washing a respected specialization within the textile industry. In many ways, the wash section is the heart of the garment’s transformation — where fabric meets personality.

Sustainability Challenges and the Road Ahead

As the fashion industry faces increasing pressure to reduce waste, energy, and water consumption, garment washing is undergoing a paradigm shift. Traditional washing methods can consume up to 70 liters of water per garment and release microfibers and chemical effluents into waterways.

To counter this, manufacturers are embracing closed-loop systems, water recycling, and chemical-free alternatives. Brands like Levi’s and H&M have already adopted sustainable washing practices such as “Water<Less” and “Conscious Wash” programs, cutting water use by up to 80%.

Moreover, digital simulation software is now being used to pre-visualize wash effects before production, reducing trial-and-error waste. The future of garment washing is digital, data-driven, and environmentally conscious.

Cultural Impact: From Factories to Fashion Statements

Garment washing doesn’t just influence production — it shapes culture. The “washed look” represents authenticity, comfort, and individuality. A pair of faded jeans, for example, is more than clothing — it’s a symbol of freedom and rebellion that transcends generations. Similarly, soft-washed T-shirts and vintage-washed jackets evoke nostalgia and familiarity — connecting wearers emotionally to their clothes.

This emotional connection is why garment washing will always be more than a technical step. It’s storytelling through texture, color, and feel — a conversation between maker and wearer.

Conclusion: Beyond the Rinse

Garment washing is where science meets soul. It’s a world of bubbling water, whirring drums, chemical alchemy, and human creativity. Every fade, crease, and touch of softness is a result of countless experiments, innovations, and skilled hands working in harmony.

“Beyond the Rinse” reminds us that behind every comfortable shirt or perfectly aged pair of jeans lies a story of chemistry, craftsmanship, and care. As the industry moves toward greener technologies and smarter production, garment washing continues to evolve — proving that even after the rinse, there’s always more to discover, refine, and celebrate.