Comprehensive Guide to Washing Chemicals in Textile & Garment Industry

Introduction

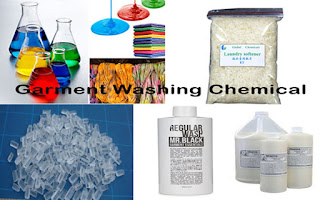

Washing is a crucial stage in the textile and garment industry. It not only improves the aesthetic appeal of fabrics but also ensures hygiene, softness, and color fastness. The washing process involves a variety of chemicals, each serving a specific purpose—from cleaning and bleaching to softening and finishing.

Selecting the right washing chemicals is essential for fabric quality, environmental safety, and operational efficiency. This guide provides a detailed overview of commonly used chemicals in textile washing, explaining their functions, applications, advantages, and safety measures.

1. Sizing and Desizing Chemicals

1.1 Amylase Enzymes

-

Function: Amylase enzymes break down starch-based sizing applied during weaving. Removing sizing is necessary before bleaching or dyeing.

-

Usage: Typically used in desizing baths at 50–60°C with pH 6–7.

-

Advantages: Reduces fabric stiffness, allows better penetration of dyes.

-

Precautions: Avoid inhalation; prolonged skin contact may cause irritation.

1.2 Cellulase Enzymes

-

Function: Break down cellulose impurities and microfibrils on cotton fabrics.

-

Usage: Applied in bio-polishing to improve smoothness, reduce pilling, and enhance fabric luster.

-

Advantages: Eco-friendly alternative to harsh chemicals; maintains fabric strength.

-

Precautions: Do not use on synthetic fabrics unless blended with cotton carefully.

2. Bleaching Chemicals

2.1 Hydrogen Peroxide (H₂O₂)

-

Function: A strong oxidizing agent that whitens cotton and viscose fabrics.

-

Usage: Applied under controlled temperature (90–95°C) and pH 9–10, often with stabilizers to prevent fiber damage.

-

Advantages: Efficient whitening, eco-friendly if properly treated.

-

Precautions: Avoid direct contact with skin; can cause burns.

2.2 Sodium Hypochlorite (NaClO)

-

Function: Chlorine-based bleach for cotton and blended fabrics.

-

Usage: Used at low concentration (0.5–2%) to prevent fiber damage.

-

Advantages: Fast-acting bleaching effect.

-

Precautions: Highly corrosive; can weaken fibers; generate toxic gases if mixed with acids.

2.3 Sodium Percarbonate

-

Function: Oxygen-based eco-friendly bleaching agent.

-

Usage: Dissolves in water to release hydrogen peroxide; used for color-safe bleaching.

-

Advantages: Biodegradable, less harmful to the environment.

-

Precautions: Store in a dry, cool place; avoid mixing with acids.

3. Detergents & Surfactants

3.1 Non-Ionic Surfactants

-

Function: Reduce surface tension, improve wetting, and ensure uniform chemical penetration.

-

Usage: Used in pre-wash, enzyme baths, and dyeing auxiliaries.

-

Advantages: Compatible with other chemicals, minimal foam formation.

3.2 Anionic Detergents

-

Function: Remove grease, oil, and particulate matter from fabrics.

-

Usage: Essential in scouring and pre-wash baths.

-

Precautions: Can irritate skin; proper protective gloves required.

3.3 Cationic Surfactants

-

Function: Used as softeners and antistatic agents.

-

Usage: Applied in finishing baths to improve hand feel.

-

Advantages: Enhance softness and manage static electricity.

4. Scouring Agents

4.1 Sodium Hydroxide (NaOH)

-

Function: Strong alkali used for scouring cotton, removing waxes, fats, and pectins.

-

Usage: Applied at 2–5% concentration at high temperature (90–100°C).

-

Advantages: Efficient cleaning; prepares fabric for dyeing.

-

Precautions: Highly caustic; requires full PPE.

4.2 Sodium Carbonate (Soda Ash)

-

Function: Alkali buffer and water softener.

-

Usage: Pre-treatment, pH adjustment in washing baths.

-

Advantages: Enhances washing efficiency, reduces scaling.

5. Enzyme Chemicals

5.1 Cellulase

-

Function: Bio-polishing agent for cotton, removes microfibrils to reduce fuzz and pilling.

-

Usage: Applied at 50–60°C, pH 4.5–5.5.

-

Advantages: Eco-friendly, improves fabric smoothness and appearance.

5.2 Amylase

-

Function: Removes starch sizing from woven fabrics.

-

Usage: Used before bleaching to ensure complete chemical penetration.

6. Softening Chemicals

6.1 Cationic Softeners

-

Function: Improve the hand feel of cotton and blended fabrics.

-

Usage: Applied during the final wash at low temperature.

-

Advantages: Soft touch, antistatic properties.

6.2 Silicone-Based Softeners

-

Function: Provides lubricity, smoothness, and improved fabric drape.

-

Advantages: Long-lasting softness, less chemical residue.

7. Anti-Redeposition Agents

-

Function: Prevent dirt and color from redepositing on fabric during washing.

-

Examples: Polyacrylates, Carboxymethyl Cellulose (CMC).

-

Usage: Added to washing baths, especially for reactive dye fabrics.

-

Advantages: Maintains fabric whiteness and brightness.

8. Water Treatment Chemicals

8.1 Sodium Hexametaphosphate (SHMP)

-

Function: Softens water, prevents scale and deposition in machines.

-

Usage: Used in scouring and washing baths with hard water.

8.2 EDTA (Ethylenediaminetetraacetic Acid)

-

Function: Chelating agent, binds metal ions.

-

Usage: Prevents water hardness from affecting washing efficiency.

-

Precautions: Must be properly treated before wastewater disposal.

9. Color Fixing Agents

9.1 Cationic Fixatives

-

Function: Improve dye fixation, reduce color bleeding.

-

Usage: Applied after reactive dyeing at low temperature.

9.2 Alkyl Quaternary Ammonium Salts

-

Function: Enhance color fastness, softening effect simultaneously.

10. Optical Brighteners

-

Function: Enhance whiteness by absorbing UV light and emitting blue fluorescence.

-

Types: Stilbene derivatives, fluorescent whitening agents.

-

Usage: Applied during final wash, especially for cotton and synthetics.

-

Advantages: Bright, vibrant fabrics without harsh chemicals.

11. Stain Removal Chemicals

11.1 Oxidizing Agents

-

Examples: Hydrogen peroxide, sodium perborate.

-

Function: Break down colored stains via oxidation.

-

Usage: Applied to white or color-safe fabrics.

11.2 Reducing Agents

-

Example: Sodium hydrosulfite.

-

Function: Remove stubborn dye or discoloration stains.

-

Precautions: Handle carefully, may release sulfur gases.

12. Specialty Chemicals

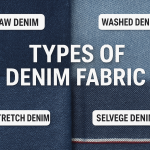

12.1 Ozone

-

Function: Eco-friendly bleaching and fading of denim.

-

Advantages: Reduces water and chemical consumption, no harsh residues.

12.2 Stone Washing Enzymes

-

Function: Simulate abrasion, create worn or distressed effects on denim.

-

Advantages: More consistent and eco-friendly than pumice stones.

13. Safety and Environmental Considerations

-

PPE: Gloves, masks, goggles required for handling chemicals.

-

Ventilation: Ensure proper air circulation to prevent inhalation hazards.

-

Wastewater Treatment: Neutralize and treat all effluents to prevent environmental pollution.

-

Storage: Store chemicals in labeled, secure containers.

Conclusion

The correct selection and application of washing chemicals directly affect fabric quality, color, softness, and durability. Modern textile industries are increasingly shifting toward enzymatic, oxygen-based, and eco-friendly chemicals to reduce environmental impact while maintaining high-quality finishes.

By understanding the function, advantages, and precautions for each chemical, garment factories can ensure efficient, safe, and sustainable washing processes.

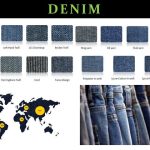

Table: Washing Chemicals in Textile & Garment Industry

| Chemical / Class | Function | Typical Usage | Recommended Concentration | Safety & Precautions |

|---|---|---|---|---|

| Amylase Enzymes | Break down starch sizing | Desizing of woven fabrics | 0.5–2 g/L at 50–60°C, pH 6–7 | Avoid inhalation, skin contact may irritate |

| Cellulase Enzymes | Remove microfibrils, reduce pilling | Bio-polishing of cotton | 1–2 g/L, 50–60°C, pH 4.5–5.5 | Do not use on synthetics alone |

| Hydrogen Peroxide (H₂O₂) | Oxidizing agent for bleaching | Bleaching cotton, viscose | 2–6% at 90–95°C, pH 9–10 | Corrosive; avoid direct contact with skin |

| Sodium Hypochlorite (NaClO) | Chlorine bleach | Cotton & blends | 0.5–2% | Highly corrosive; avoid acids; can damage fibers |

| Sodium Percarbonate | Oxygen-based bleaching | Eco-friendly bleaching | 1–3% at 60–80°C | Store in cool, dry place; avoid acids |

| Non-ionic Surfactants | Wetting agent | Pre-wash, enzyme baths | 0.5–2% | Low hazard; avoid excessive foam |

| Anionic Detergents | Remove oils, grease | Scouring, pre-wash | 1–3% | Can irritate skin; use gloves |

| Cationic Surfactants | Softener, antistatic | Finishing baths | 0.5–1% | Avoid eye contact; slippery if spilled |

| Sodium Hydroxide (NaOH) | Strong alkali, scouring | Remove waxes, pectins | 2–5% at 90–100°C | Highly caustic; full PPE required |

| Sodium Carbonate (Soda Ash) | Alkali buffer, water softener | Pre-treatment, pH control | 1–3% | Avoid inhalation; mild irritant |

| Cationic Softeners | Improve hand feel | Final wash | 0.5–1% | Avoid prolonged skin contact |

| Silicone-Based Softeners | Lubricity & smoothness | Softening finish | 0.2–0.5% | Non-toxic; avoid high temperatures |

| Polyacrylates / CMC | Anti-redeposition | Washing to prevent soil | 0.5–1% | Low hazard |

| Sodium Hexametaphosphate (SHMP) | Water softener, chelating | Hard water treatment | 0.5–1% | Avoid inhalation of dust |

| EDTA | Chelating agent | Prevent scale formation | 0.2–0.5% | Proper wastewater treatment needed |

| Cationic Fixatives | Improve dye fixation | Post-dyeing | 0.5–1% | Avoid eye contact |

| Alkyl Quaternary Ammonium Salts | Color fixation & softening | Post-dyeing | 0.2–0.5% | Avoid prolonged skin contact |

| Optical Brighteners | Enhance whiteness | Final wash | 0.1–0.3% | Avoid ingestion; non-toxic topically |

| Sodium Perborate | Oxidizing stain remover | White fabrics | 1–3% | Avoid mixing with acids |

| Sodium Hydrosulfite | Reducing agent for stains | Remove discoloration | 1–2% | Releases sulfur gases; ventilate |

| Ozone | Eco-friendly bleaching/fading | Denim finishing | Generated in situ | Highly reactive; proper containment |

| Stone Washing Enzymes | Abrasion & fading effect | Denim finishing | 0.5–1% | Avoid mixing with strong acids |