Industrial Washing & Finishing Machines — Case Studies of Yılmak, Tonello, Brongo, Danış, Nexia

In the textile / garment finishing / denim wash sector, certain manufacturers have built reputations for innovation, efficiency, garment effect diversity, environmental sustainability, and robust industrial scale. Among these are Yılmak (Turkey), Tonello (Italy), Brongo (Italy), Danış / Danis Machine (Turkey), and Nexia / De Franceschi (Italy). Each has distinctive product lines, machine configuration choices and engineering trade-offs. Below I describe each, their configurations, unique features, comparisons, and then general summary of their strengths and limitations.

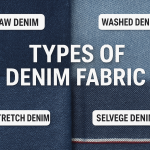

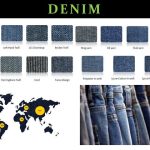

1. Yılmak (Turkey)

Overview:

Overview:

Yılmak Makina Sanayi is a Turkish company specializing in large industrial garment washing machines, especially for denim and finishing, sustainable / resource-saving machines, with exports globally. Yilmak+3Yilmak+3Manufacturer Directory – Manuzone+3

Some of Yılmak’s product lines:

-

Rainbow HS-W Series (High Speed Washing Machines) Yilmak

-

EcoGreen Series (EG-W) Yilmak

-

Rainforest RF Series Yilmak

Machine Configuration & Key Features:

Here are some technical details and unique configuration features from Yılmak’s offerings:

| Series | Drum volume / diameter / depth | Variable speed / spin / installed power | Other features |

|---|---|---|---|

| Rainbow RB 25 HS-W | 250 liters, drum Ø 795 mm, depth 500 mm | 0–650 rpm variable speed, installed power ~4 kW | High rotation speed for hydro-extraction; “8-point individual balancing system” allows high G-force (~400 G) during centrifuge; support for nebulising / nano-bubble / ozone systems. Yilmak |

| RB 60 HS-W | 575 L, Ø 1000 mm, depth 730 mm | 0-650 rpm, ~11 kW | Similar high speed; scale-up version. Yilmak |

| EcoGreen EG-W 25 | ~260 L, Ø 817 mm, depth 500 mm | low rpm (0-40 rpm for some operations), lower installed power (~0.75 kW) | Designed for water/energy conservation; pumped water circulation system removed (“pumpless”) possibly in updated models; green / lighter consumption. Yilmak |

| Rainforest RF 25 | 250 L, Ø 797 mm, depth 500 mm | 0-100 rpm, installed power ~1.1 kW | Emphasis on process efficiency: lower resource usage (water, steam, chemicals), faster processing; “Rainforest technology” for resource saving in garment washing. Yilmak |

Configuration Elements / Internal Architecture:

From Yılmak’s published info one can deduce:

-

Drum design: Large perforated or open pocket drums (especially for denim / finishing garments), able to withstand heavy mechanical action, sometimes capable of high G extraction (centrifuge).

-

Balancing system: E.g. “8-point individual balancing” in HS-W series to allow high speed spinning with reduced vibration or damage risk.

-

Variable speed motors: Inverter-driven motors allowing smooth speed changes from slow wash/tumble to very high spin.

-

Material selection: Stainless steel for drums / water-touching surfaces to resist corrosion, especially when chemicals / dyes are used. Outer frames built robust to support weight, vibrations.

-

Water circulation / pumping / valves: Some series include “pumpless water circulation” (EcoGreen) to reduce equipment cost and maintenance, possibly using gravitational flow or specially designed internal channels. Also, support for optional attachments: ozone, nano-bubble, nebulizing etc.

-

Control systems: PLC or similar electronic control, with programmable cycles, speed settings, G factor, time, etc. Real-time control of safety features (overload, imbalance, door interlocks, etc.).

Pros & Strengths:

-

Strong emphasis on sustainability: lower water / chemical consumption, resource efficiency.

-

High capacity machines for industrial scale: large drum volumes.

-

Flexibility: options for effect finishes, attachments (ozone, nano-bubble), versatile cycle programming.

-

Good after-sales and export presence: many factories globally use Yılmak equipment. Yilmak+2Yilmak+2

Limitations / Trade-offs:

-

High initial cost and physical footprint / infrastructure: need strong foundations, electrical power, water, chemical supply, drainage.

-

Complexity: maintenance, spare parts, skilled operators required.

-

For small‐scale users or smaller factories, water savings may still be overshadowed by overhead (energy, chemical handling etc.).

2. Tonello (Italy)

Overview:

Overview:

Tonello is an Italian manufacturer, well known in the denim finishing and processing sector. They provide washing/dyeing/wear-effect machines, and especially tools for sampling and scaling processes. Indian Textile Magazine+2Innovation in Textiles+2

Key Products / Innovations:

-

G1 Lab — a compact dyeing / sampling machine by Tonello. Indian Textile Magazine

-

Evolution 3 line — newer generation washing/dyeing machines focusing on reduced resource consumption. Innovation in Textiles

Technical / Configuration Highlights:

From the G1 Lab machine:

-

Designed for sampling and replicating production-level finishes but on very small loads (50 g to 1 kg), so the user can test recipes/recipes, washes etc. before deploying at scale. Indian Textile Magazine

-

Keeps liquor ratio similar to large production machines, so the behaviour of washes (chemical concentration, mechanical action, etc.) is close to full-scale. This helps reproducibility. Indian Textile Magazine

-

Electrical heating rather than steam in the laboratory model (to allow placement flexibility). Indian Textile Magazine

-

Remote management: Tonello offers “MAGO” remote assistance for recipe / process monitoring. Indian Textile Magazine

From Evolution 3:

-

Advances to reduce water usage, energy consumption, maintenance cost. Features include: high efficiency motors, improved belts / transmission, better drum welds (robot-welded) for durability. Innovation in Textiles

-

Use of new inverters to improve motor control, reduce vibration and mechanical stress. Innovation in Textiles

-

Stainless steel materials, especially in contact with baths, to resist corrosion. Innovation in Textiles

Pros & Strengths:

-

Very good for producers who need effect finishes (stone wash, enzyme, etc.) with reproducibility.

-

Strong R&D: sampling machines allow trial before scale. Helps reduce waste / defective production.

-

High build quality and durability.

Limitations / Trade-offs:

-

Premium pricing.

-

Laboratory-scale machines are not for mass volume; production machines require infrastructure.

-

For certain effect finishes, consumables / chemicals still significant cost.

3. Brongo (Italy)

Overview:

Overview:

Brongo S.r.l. is an Italian company that produces industrial washing machines both for garments (denim, fashion) and linen, with many models for different spin-speeds and finishing needs. They are appreciated for robust construction and specific garment effect capabilities. acimit.it+1

Product / Model Types:

-

MODEL L: open pocket drum, low spinning speed, compact machines. brongo.com+1

-

MODEL LM: open pocket drum, medium spin speed. brongo.com

-

MODEL LCO: open pocket drum, high spinning speed, with automatic self-balancing during extraction. brongo.com

From catalog entries:

-

Capacity variants: multiple drum volumes (e.g. 1.2 m³, 2.3 m³, 3.5 m³, 4.2 m³, 5.2 m³) depending on model. DirectIndustry

-

Materials: stainless steel for the frame / shell, front frames, panels. Compact design: control panel / electric box integrated into frame. brongo.com+1

Configuration Details:

-

Drum design: Open pocket drum — means the drum has large “pockets” / indentations rather than just smooth perforations, to help with mechanical effect and better liquor action.

-

Spin / extraction speeds: Low, medium, high depending on model; higher models include self-balancing features to handle loads at high spin.

-

Low liquor ratio: Brongo’s machines are designed to minimize the gap (space) between drum and outer shell, thus reducing “inactive” liquid volume and reducing water usage and heating cost. DirectIndustry+1

-

Controls / Electric box: compact integrated electrical box inside frame; front panel control. brongo.com+1

Pros & Strengths:

-

Flexibility in spin speed gives users control over extraction vs effect.

-

Good mechanical design; stainless steel construction promotes durability.

-

Low liquor ratio helps save water / energy.

Limitations / Trade-Offs:

-

As with all high-spin machines, vibration / imbalance risks if load not well distributed. Maintenance of self-balancing / bearing / rotor components more demanding.

-

The larger the size, the more readiness needed for high torque motors, strong foundations, service.

4. Danış Machine / Danis Makina (Turkey)

Overview:

Overview:

Danis Machine (also spelled Danış) is a Turkish manufacturer of industrial washing and finishing machines. Has decades of experience; strong in exports (Bangladesh, India, Pakistan etc.). Their product lines include washing / stone washing / steam dryers / extractors / ozone / dry-process machines. Apparel Views+2danismakine.com.tr+2

Key Series:

-

Volcano Series — sustainable washing series. danismakine.com.tr

-

Sample / smaller volume machines also exist (Volcano Sample). danismakine.com.tr

Technical / Configuration Details:

From the Danış “Volcano Series” spec sheet:

-

Capacity / Volume: Ranges from ~354 to ~5,127 liters of drum volume. danismakine.com.tr

-

Load in kg: approx. 35 kg to ~510 kg depending on model. danismakine.com.tr

-

Liquor ratio: 1:2 to 1:3 (i.e. one part solid to 2-3 parts liquid) depending on recipe. Low liquor ratios are more efficient (less water / chemical / heating). danismakine.com.tr

-

Sprinkler technology: Danış uses “sprinkler technology” to give extra effects on garments without extra energy cost. (Sprinkling water over garments rather than immersing fully? Or shower effect?) danismakine.com.tr

-

Patented eco-beaters: Danış Volcano line includes “6 eco-beaters”, a patented beater design. The beaters are parts inside the drum that help mechanical action; efficient beaters help wash effect while reducing damage and energy. danismakine.com.tr

-

Materials: All water-touching surfaces are stainless steel, especially 316 SS where needed (higher corrosion resistance). Electronics / mechanical parts imported from Europe / South Korea. danismakine.com.tr

-

Add-ons / optional features: The machines can integrate Stone Wash technology, Ozone system, Nano Bubble system; also upgradeable with Jet Dyeing system. danismakine.com.tr

Pros & Strengths:

-

Strong in balancing environmental concerns: water and chemical savings, energy efficiency.

-

Large capacity range allows scaling from medium to large garment factories.

-

Optional attachments provide flexibility for different wash effects / finishing styles.

Limitations / Trade-Offs:

-

Larger machines need bigger investment, infrastructure.

-

Complexity in operation: requires trained staff, good maintenance.

-

For small factories or shops, cost per unit wash may be high unless utilization is good.

5. Nexia / De Franceschi (Italy)

Overview:

Overview:

Nexia (De Franceschi is a historic Italian brand) produces industrial washing / dyeing / finishing machines. Their strength includes effect finishes (stone washing, ozone, stoneless systems), environmental performance (water / energy / chemical savings), wide range (experimental/lab machines up to large production). Indian Textile Magazine+2Textile & Fashion News+2

Key products / Technologies:

-

Ozone Production System (wet and dry ozone processing) Textile & Fashion News+1

-

Stone Washing Machines / Stoneless System (e.g., Nexstone, which is a patented device to produce abrasion without pumice stones) Textile & Fashion News+1

-

Hydro extractors, dryers, both for production and lab capacities. Indian Textile Magazine+1

-

Lab / small-scale variants (3-17-40 kg) and production ones (100-180 kg etc.) Indian Textile Magazine

Configuration Details:

-

Lab-scale machines: Smaller drums, more precise control (temperature, time, chemical / exhaust etc.), built to replicate large-scale effects.

-

Production machines: Larger capacity drums, higher extraction, possibly vented / condensing dryers, large hydro extractors.

-

Ozone / stoneless systems: In ozone systems, ozone is generated (via ozone generators), used as oxidizer / bleaching agent (or effect agent), reducing chemical (e.g. chlorine, bleach) usage. Stoneless systems produce abrasion or fading without pumice; better for environmental disposal, reduced grit, etc.

-

Material and instrument quality: Stainless steel drums, precise welds, corrosion-resistant surfaces. Efficient motors/inverters. Good control panels. Textile & Fashion News

Effect on Environmental / Operational Metrics:

-

According to reports, using Nexia’s newer smart machines / effect finishes, water consumption can be reduced by up to 85%, chemical use by ~50%, and energy consumption by ~40% in some processes (wet/dry/ozone etc.). Textile & Fashion News

6. Comparative Analysis: Features, Use Cases, Trade-Offs

After examining these manufacturers, we can distill what makes them similar / different, how to choose, what configurations are important, etc.

| Dimension | Important configuration parameter | How different brands address it |

|---|---|---|

| Liquor ratio (ratio of wash bath volume to mass of garments) | Lower liquor ratio → less water, chemical, energy for heating, faster cycles; but requires better mechanical mixing, drum design, evenness | Danis’s Volcano: 1:2 to 1:3; Nexia lab machines replicative; Yılmak’s EcoGreen & Rainforest focus on these too. |

| Mechanical action / beater / drum design | Pocket drum, open pocket, beaters, lifters, etc.; affect how garments rub / tumble → effect style (stone wash / fade etc.) | Brongo: open pocket drums; Danis: eco-beaters; Tonello: drum welds, able to replicate full effect in lab. |

| Spin / extraction speed / G-force | High extraction reduces drying time, can reduce energy in dryer; but needs robust bearings, balancing systems, appropriate motor and control. | Yılmak Rainbow HS-W: up to 650 rpm and high-G extraction with balancing; Brongo LCO has automatic self balancing; Tonello Evolution 3 includes inverters to better control spin and reduce mechanical stress. |

| Auxiliary / finishing attachments | Ozone, nano-bubble, stoneless systems, stone wash, enzyme wash, etc. These allow effects, reduce environmental damage or cost, differentiate finishes. | Danis’s optional ozone/nano bubble; Nexia’s ozone and Nexstone; Yılmak allows nebulizing, nano bubble, ozone; Tonello labs replicate real production recipes. |

| Material / corrosion resistance | Stainless steel (316 SS where needed), good welds, durable bearings, high-quality motors. | All brands emphasize stainless steel, corrosion resistance, robotic welds (Tonello), etc. |

| Control systems / motors / inverters | Ability to adjust speed, time, heating, automation; PLC / digital controls; remote control; safety. | Tonello’s remote assistance; Danis uses inverters; Yılmak’s variable speed; Nexia’s smart evolution machines. |

| Sustainability / resource efficiency | Water, chemical, energy usage; ability to reuse water; lower emissions; environmental certifications. | Brands like Yılmak, Danis, Nexia put sustainability as central; EcoGreen, Rainforest, Volcano, ozone, stoneless, etc. |

7. Typical Machine Lifecycle & Wash Cycle Configuration

To understand what configurations are inside these machines, here’s a generalized breakdown, using these brands’ typical machines as examples.

-

Preparation / loading:

-

Garments loaded into large drum. For big machines, gates / tilting doors / pneumatic opening can be used. (Tonello G1 for instance has a wide door, pneumatic opening for loading/unloading.) americanplantandequipment.com+1

-

Pre-treatment if any (e.g. pre-soak / enzyme / stone / chemical soak).

-

-

Wash / agitation:

-

Water (and/or steam) introduced via valves; temperature raised via heating elements or steam injection.

-

Mechanical motion: drum rotation, possibly reverse direction, tumble or pocket drum design, beaters or lifters create rubbing. Brands such as Danis Volcano with eco-beaters or Brongo with open pocket drums aim to maximize effectiveness while controlling garment wear.

-

-

Effect / finishing steps:

-

Stone wash / enzyme / bleaching / ozone / nano bubble etc. For example, ozone systems in Nexia, nano-bubble / ozone in Yılmak, Danis.

-

Use of “stoneless” abrasion devices or auxiliary beads instead of pumice stones (safer, less waste).

-

-

Rinse cycles:

-

Multiple rinses to remove chemicals / dyes; possibly with lower water usage via optimized flow.

-

-

Extraction / Spin / Hydro-extraction:

-

Drum spins at high RPM; self-balancing systems or special shock absorbers to maintain stability; water removed. High G extraction reduces moisture content, saving on drying time. Yılmak’s HS-W series can reach high G values; Brongo LCO has automatic self-balancing.

-

-

Drying / Post-processing:

-

After extraction, possible drying (steam / gas / electric) depending on the washing plant. Some brands offer dryers, hydro extractors etc. For example, Nexia has dryers and hydro extractors; Danis has steam dryers.

-

-

Control & safety:

-

PLC or digital controllers to set wash program, timing, temperature, spin speed.

-

Sensors: water level, temperature, vibration/imbalance, door interlocks, etc.

-

Safety: over-heat protection, imbalance detection, emergency shutdown.

-

8. Use Cases / Who Should Use Which Brand / Machine Type

Based on configuration and features, here are typical use-cases / recommendations:

| Factory type / Goal | What features are most critical | Which brands / series are well suited |

|---|---|---|

| Large-scale denim finishing with high volume, many washes per day | High capacity drums, high spin extraction, sustainability (low water/chemical), durability, after-sales service | Yılmak Rainbow HS-W, Danis Volcano large models, Tonello production machines |

| Factories wanting effect finishes (stone wash, enzyme wash, bleaching etc.) with environmental compliance | Ability for finishing attachments (ozone, nano bubble, stoneless), controlled mechanical action, safe finishing, reproducibility | Nexia, Danis, Yılmak, Tonello |

| Medium/smaller garment factories aiming to reduce water / power bills | Machines with low liquor ratio, efficient motors/inverters, sustainable series (EcoGreen, etc.) | Yılmak EcoGreen, Danis Volcano mid-size, Nexia newer models |

| Labs / sampling / R&D departments | Small load machines, precise replication of full scale finishes, ability to test recipes, remote recipe transfer | Tonello G1 Lab; Nexia lab-scale equipment |

| Factories in regions with challenging utilities (power/water) | Machines with efficient heating, low water / chemical consumption, measureable control over cycles; good support / spare parts availability | Danis, Yılmak (Turkey has good export / service network in regions), Nexia with local agents |

9. Challenges & Trade-Offs in These Machine Configurations

While the features above seem very positive, in practice there are trade-offs / challenges. Some to consider:

-

Capital cost vs operating cost: The more advanced / eco-friendly the machine, usually the higher up-front cost. Whether water / energy savings can recoup that depends on utilization.

-

Spare parts & maintenance: Machines with advanced control boards, high G-force extraction, special beaters or attachments require skilled maintenance. Downtime can be costly.

-

Uniformity of effect: Achieving consistent wash effect (color fade, abrasion, etc.) depends on many factors: loading, chemical dosage, mechanical action, drum wear. Even with good machines, variations happen.

-

Chemical / environmental regulation: Finishing with chemicals / bleaching / stone / enzyme etc. often has environmental / waste water treatment implications. Machines with ozone / stoneless / nano bubble etc. help, but the factory must have good ETP (effluent treatment plant).

-

Infrastructure demands: Adequate water supply, drainage, electrical power, skilled labour, safety retraining. Heavy machines need strong flooring; high spin machines exert large forces on frames, foundations.

10. Machine Configure – What to Look For Technical Specification & Questions

If you are deciding to buy or specify such machines, here are the configuration parameters you should explicitly check / demand, and why:

-

Drum volume (liters) and load capacity (kg): Must match your throughput; oversize wastes energy, undersize causes overloading and poor effect.

-

Liquor ratio: What minimum:maximum ratio the machine can handle; low liquor ratio saves water, energy.

-

Spin / extraction speed (rpm / G-force): Higher spin = less moisture after wash; but must have good balancing and bearings.

-

Drum design / beater / lifters / pocket type: These affect mechanical action and wash effect, garment wear.

-

Material of drum, shell, contact surfaces: Stainless steel (especially high grade like 316) for chemical resistance.

-

Motor and drive type: Induction / inverter / frequency converter; whether motor is direct drive or belt driven (industrial).

-

Control system features: PLC or digital timer; ability to set custom programs; sensors; safety features.

-

Auxiliary systems / attachments: If you need stone wash, ozone, nano bubble, stoneless etc. check if they are integrated or optional, and what maintenance they need.

-

Water heating / steam / cooling arrangements: Heating type (electric / steam / gas), insulation, cooling / condensers if needed.

-

Energy consumption, water consumption, chemical usage data: Vendors should provide typical data (e.g. kWh per kg wash, liters per kg, chemical consumption) so you can compute operating cost.

-

Mechanical robustness, maintenance support, spare parts availability: Especially in your region.

-

Safety / environmental compliance: Emissions, wastewater treatment, chemical disposal, worker safety, etc.

11. Summary & Comparison

Here’s a high-level summary:

| Brand / Line | Strengths / Unique Selling Points | Best For | Considerations / Needs |

|---|---|---|---|

| Yılmak (Rainbow HS-W, Rainforest, EcoGreen) | High extraction, sustainability, flexible finishing, large capacity, good global service | Factories doing heavy denim / garment finishing with high throughput and environmental targets | Needed infrastructure; high initial cost; skilled maintenance; capital for attachments |

| Tonello | Lab-to-production replication; strong finishing effect; remote control; high build quality | Brands or factories designing new washes / effect finishes; R&D; premium denim / fashion brands | Premium cost; smaller machines less suited for high volume by themselves; consumables / effect washes add cost |

| Brongo | Robust build; variety of spin levels; designs optimized for water savings; low liquor ratio; strong materials | Medium-to-large factories that need flexibility (low to high spin), effect finishes, and durability | Needs good maintenance; high-spin machines can stress components; cost vs returns must be calculated |

| Danis (Volcano etc.) | Very strong focus on sustainability; large capacity range; optional effect attachments; patented beaters; good export track record | Factories wanting to modernize, save water/chemicals, comply with environmental norms; large factories in Asia / Middle East etc. | Need to ensure spare parts & support; training; manage chemical & finishing effect tradeoffs |

| Nexia / De Franceschi | Effect finishing alternatives (ozone / stoneless), lab & production scale; environmental reduction; broad product line; Italian engineering & heritage | Factories wanting modern, clean finishes, sustainability, diversified finishing options, good after-sales | Cost; sometimes complexity; maintaining effect consistency; ensuring ETP / environment compliance; energy and chemical sourcing constraints |