1. Incoming goods inspection ,Qc shade seggreation & Lot/Batch preparation

-

Visual & physical inspection of rolls/sheets: check for damage, stains, oil, prior finishes, size type (starch, PVA, resin), GSM, and composition labels.

-

Sampling: take laboratory swatches for small-scale trials if the fabric or previous processing is unknown.

-

Weighing & batching: determine batch size (kg) and prepare batch sheets.

-

Chemical & utility check: verify inventory for enzymes, peroxide, acids, surfactants, sequestering agents, softeners, and availability of hot water/steam, compressed air, effluent system ready.

-

Health & safety: ensure PPE, MSDS accessible, and staff briefed.

Reason: misidentifying sizing (e.g., PVA vs starch) or previous treatments results in failed desizing or fiber damage downstream.

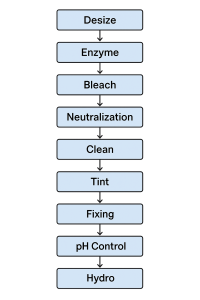

2. Desizing — purpose and method

Purpose: Remove film-forming sizing materials (starch, carboxymethylcellulose (CMC), PVA, waxes) used in weaving/warping. Proper desizing restores absorbency and preps fibre for bleaching/dyeing.

Process choices:

-

Enzymatic desizing (α-amylase for starch): widely used, effective at moderate temperatures and pH. Eco-friendly.

-

Chemical desizing (caustic / alkaline): used for PVA and stubborn sizing; requires higher temperatures / alkali and sometimes special PVA-degrading agents.

-

Oxidative or hydrolytic treatments for specific sizing chemistries.

Typical operating window (starch):

-

Temperature: 60–70 °C

-

pH: 6.5–8.5 (enzyme-specific)

-

Enzyme dose: 0.1–0.5 g/L (or according to supplier)

-

Time: 20–30 minutes

-

Liquor ratio (L:R): 1:5 to 1:10 for continuous padded or jet wash lower L:R can be used.

Key control checks:

-

Iodine test for residual starch.

-

Absorbency test (drop test).

-

Monitor bath conductivity and pH.

Notes for PVA: PVA requires specific alkali/heat or PVA-degrading enzymes—confirm sizing type before selecting method.

3. Enzyme treatment (Stone Enzyme /bio-scouring / bio-polishing)

Purpose: Remove residual natural impurities (pectins, proteins, waxes) and fibrils to improve absorbency, whiteness, smoothness and reduce pilling.

Enzyme types & uses:

-

Pectinases: remove pectins in cotton blends.

-

Proteases: for proteinaceous contaminants (wool blends or silks).

-

Cellulases (bio-polishing): remove microfibrils to give softer hand, reduce pilling (low concentrations, tightly controlled).

-

α-Amylase: overlaps with desizing for starch removal.

Operating guidelines:

-

Temperature: 40–60 °C (depends on enzyme, cellulases tend to work at lower temp around 45 °C)

-

pH: 4.5–8.5 (enzyme specific; cellulases prefer mildly acidic to neutral)

-

Time: 20–60 minutes

-

Enzyme dose: supplier specified — often 0.1–1 g/L

-

Liquor ratio and gentle mechanical action to avoid surface damage.

Critical controls:

-

Don’t expose active enzyme bath to high alkalinity or temperature that denatures it.

-

After enzyme treatment, perform a thorough wash to stop enzyme action (alkaline or hot water can deactivate, but controlled neutralization/rinse is preferred).

Benefits: Lower chemical consumption, better whiteness, reduced energy use vs aggressive chemical scouring.

4. Bleaching (oxidative whitening)

Purpose: Remove natural color impurities to prepare a white/base substrate for dyeing or tinting. Hydrogen peroxide (H₂O₂) is the industrial standard for cellulosic fibers.

Key chemicals:

-

Hydrogen peroxide (stabilized solutions)

-

Alkalis (soda ash, caustic in controlled small amounts)

-

Stabilizers / activators (sodium silicate, sodium stannate or commercially formulated stabilizers)

-

Sequestering agents / chelants (EDTA types or safer alternatives) to bind metal ions which catalyze peroxide decomposition.

Operating window (typical):

-

Temperature: 60–70°C (often 60–70 °C)

-

Time: 30–90 minutes

-

H₂O₂ concentration: 2–6 g/L (depending on whiteness target and fabric)

-

pH: 9–10.5 during bleaching (alkaline medium makes peroxide more reactive)

-

Liquor ratio: 1:5–1:10 (continuous lines lower)

Process notes:

-

Control of metal ions is crucial; trace iron/copper accelerate peroxide decomposition and cause uneven bleaching or fabric damage.

-

Peroxide stability: avoid sudden temperature rise or addition of incompatible chemicals.

-

Follow supplier’s recommendations for stabilizer selection and dose.

Quality metrics:

-

Whiteness index or reflectance measured by spectrophotometer.

-

Tensile strength tests before/after bleaching to detect over-oxidation.

5. Neutralization (post-bleach)

Purpose: Remove residual peroxide and bring fabric pH to a safe level before further chemistry; prevents fiber damage and prepares for detergents/dyes.

Chemistries used:

-

Acids: acetic acid, citric acid in diluted form to lower pH.

-

Reducing agents (if needed to destroy residual oxidant): sodium bisulfite or sodium thiosulfate (used cautiously as they can affect subsequent dyeing).

Operating notes:

-

Target pH after neutralization: approx 5.0–6.5 (depends on next step; dyeing often needs specific pH)

-

Add acid slowly while continuously stirring and monitoring pH to avoid localized over-acidification.

-

If residual H₂O₂ is measured, a short reducing step may be applied but must be followed by thorough rinsing.

Controls:

-

Continuous pH monitoring; do not overshoot.

-

Test strips or pH meter in pad/exhaust are used.

6. Clean / Detergent wash

Purpose: Remove emulsified oils, surfactant-soluble contaminants, and residues from previous steps—ensures a clean substrate for even tinting/dyeing.

Chemicals:

-

Non-ionic surfactants (excellent wetting and emulsification)

-

Low foaming detergents for high-mechanical washers

-

Builders/sequesterants to aid soil removal

Operating parameters:

-

Temperature: 40–60 °C

-

Time: 10–30 minutes

-

Detergent dose per supplier guidelines (commonly 1–5 g/L depending on machine type)

Notes:

-

Avoid high foaming systems in continuous lines.

-

Final conductance and turbidity of rinse indicate cleanliness.

7. Rinse (counter-current recommended)

Purpose: Remove soluble chemicals and reaction by-products after each major step to avoid carryover and interference.

Best practices:

-

Counter-current rinsing saves water: final rinse water is cleanest and flows to earlier rinse step.

-

Typical sequence: 2–4 rinses with rising water quality.

-

Measure conductivity, pH, and turbidity to determine adequacy of rinses.

Parameters:

-

Ambient to slightly warm depending on carryover chemical solubility.

-

Each rinse 5–15 minutes in batch systems; continuous systems sized accordingly.

Water management: Reuse and recovery (e.g., treat first rinse for reuse) lowers effluent load.

8. Tinting (light shade application)

Purpose: Apply a pale shade or shade correction to get consistent appearance or achieve a desired pastel tone on bleached substrate.

Dye selection:

-

Use reactive dyes for cellulose (cotton), disperse for synthetics, acid dyes for protein fibres. For tinting on bleached cotton, low-strength reactive dyes are common.

-

Choose auxiliary salts (sodium sulfate) and alkali (soda ash) based on dye class.

Application systems:

-

Padding: fabric passes through pad box with dye liquor and squeezed to an uptake level.

-

Exhaust (vat/jet): low-shade dyeing at controlled temperature.

-

Pad-batch: pad then hold for fixation at ambient or mild temperature.

Controls:

-

Bath exhaustion monitoring and even pick-up (pickup % in padding).

-

Shade reproducibility checks with spectrophotometer.

Important: If tinting is barely perceptible, ensure fixation does not cause uneven blotching; pilot trials on lab scale recommended.

9. Fixing (dye fixation / after-treatment)

Purpose: Ensure that the applied tint/dye is securely bonded to the fibre and that unfixed dye is removed/stabilized to achieve wash-fastness and minimize skew or bleeding.

Fixation methods (depending on dye type):

-

Reactive dyes (cellulosic): alkali addition (soda ash) to form covalent bond; temperature/time control critical.

-

Disperse dyes (synthetics): heat fixation (thermosol or high-temperature exhaust).

-

Acid dyes (protein): fixation via pH and time at moderate temperatures.

-

Fixing auxiliaries: polymeric fixatives, leveling agents, or cold pad-batch fixing (allows fixation at room temperature over hours).

Example (reactive dyes):

-

After dye exhaustion, add sodium carbonate (soda ash) to reach pH ~10–11 for reactive fixation, hold at 40–60 °C for the required time, then wash out hydrolyzed/unfixed dye in a soaping step (detergent + hot water).

Follow-up steps:

-

Soaping or hot detergent wash to remove hydrolyzed/unreacted dyes.

-

Thorough rinsing to reduce unfixed dye in effluent.

Quality tests:

-

Wash fastness (ISO tests), rubbing/crocking tests, and spectral checks.

10. pH control — continuous monitoring

Purpose: Ensure correct pH at each handover point; many dyeing chemistries and finishing agents require specific pH ranges to work properly and to avoid damage.

Common set points:

-

Post-bleach neutral: pH 5–6

-

Pre-reactive dye fixation (if alkaline fixation required): pH 9.5–11

-

Softener application: often pH ~5–6 for cationic softeners

-

Final pH for dispatch: industry often targets pH 5–7 depending on fabric and end use.

Control methods:

-

Inline dosing pumps controlled by pH sensors for continuous lines.

-

Manual titration with acetic/citric acid or soda ash in batch processes.

Checks: Use both pH meter and pH strips for confirmation; calibrate meters frequently.

11. Softener application (hand feel improvement)

Purpose: Improve tactile properties—softness, drape, anti-static behavior. Softener selection affects durability and other properties (e.g., oil repellency).

Types:

-

Cationic softeners: bond well to negatively charged cellulosic fibres.

-

Silicone softeners: excellent hand, durable feel; often used in blends.

-

Non-ionic emulsions: milder, less yellowing tendency.

Process:

-

Bath application (pad or exhaust) followed by mild rinse or direct hydro-extract and dry depending on formulation.

-

Typical doses: 3–12 g/L (or specified on supplier data).

-

Temperature: 25–40 °C for pad/exhaust application.

Effects to monitor:

-

Yellowing potential (especially with some cationics).

-

Effect on dye fastness (some softeners can reduce crock/wet fastness).

12. Hydro-extraction

Purpose: Remove bulk water prior to drying—reduces drying time and energy consumption.

Equipment: Centrifugal hydro-extractors, continuous squeeze rollers, or high-speed scroll extractors.

Targets:

-

Residual moisture: 30–50% retained depending on downstream dryer; high-speed extraction can reduce to <30% for tumble dryer.

-

RPM and G-force selected based on fabric strength and machine capacity.

Precautions:

-

Balance loads to avoid mechanical damage; delicate garments require lower G-force.

13. Drying

Purpose: Bring fabric to specified final moisture content for shipment or next processing step while avoiding thermal damage or shrinkage.

Dryer types: Tumble (batch), continuous conveyor/through-feed, stenter frames (with heat-setting for synthetic blends), infrared or air-impingement dryers.

Parameters:

-

Temperature: depends on composition — cotton can tolerate higher temperatures (up to 120–140 °C air temp in stenter), polyester blends require controlled heat to prevent melting/thermal set.

-

Time/airflow: adjusted to achieve target moisture content (2–6% final for fully dry product or higher if further finishing required).

-

Tensioning in stenter for width control and heat setting.

Control points:

-

Avoid over-drying (loss of tensile strength, surface yellowing).

-

Use inline moisture sensors for endpoint control.

14. Final inspection, testing & packing

QC checklist:

-

Visual check for shades, stains, uniformity.

-

Whiteness / shade measured with spectrophotometer against standard.

-

Fastness tests (wash, rub, light) for dyed/tinted batches.

-

Dimensional checks (shrinkage), GSM validation.

-

Record batch sheet, parameters, and attach QC tags.

Packing: Use moisture barrier if hydroscopic; avoid stacking while hot or humid to prevent mildew.

15. Environmental management & effluent treatment

Main concerns: COD/BOD from detergents & organics, peroxide residues, salts (from dyeing), color from unfixed dyes, high/low pH.

Key elements:

-

Primary treatment: screening, equalization tanks.

-

Chemical treatment: pH neutralization, coagulation/flocculation to remove suspended solids and dye aggregates where applicable.

-

Biological treatment: activated sludge for biodegradable organics (detergents) after chemical pre-treatment.

-

Tertiary treatment: filtration, activated carbon, membrane filtration (RO) where water reuse is targeted.

-

Sludge handling: safe disposal or drying & disposal per regulation.

Water saving: Counter-current rinsing, reuse of rinse water after filtration, and optimized liquor ratios.

16. Safety, storage & handling

-

Hydrogen peroxide: oxidizer—store in cool, ventilated area away from organics and metals; use PPE and splash goggles.

-

Alkalis / acids: corrosive—have eyewash stations, spill kits.

-

Enzymes: potential respiratory sensitizers—use masks and avoid aerosolization.

-

Training: SOPs for chemical spills, first aid, and machine safety.

-

Fire & lint control: dryers generate lint—frequent cleaning and spark arrestors.

17. Troubleshooting (common problems & fixes)

-

Uneven desizing: misidentified sizing — verify and adjust enzyme/chemical type or mechanical action.

-

Patchy bleaching / yellowing: metal ion contamination or peroxide degradation — add chelants, check peroxide quality, adjust stabilizers; neutralize residual peroxide properly.

-

Poor dye fixation (tint fading in wash): insufficient alkali for reactive dye fixation or improper time/temperature — reprocess small batch to test re-fixation if possible.

-

High COD in effluent: overuse of detergents or poor biodegradability — switch to biodegradable surfactants and optimize dosing.

-

Excessive shrinkage or strength loss: over-bleaching/over-exposure to oxidants or high drying temperatures — reduce peroxide concentration/time or lower dryer temperature.

18. Process optimization & automation suggestions

-

PLC & SCADA automation: pH, temperature, dosing, and timing automated for repeatability and logging.

-

Counter-current rinsing & water recovery: reduces water use and effluent.

-

Enzyme optimization: lower temp enzyme systems can reduce energy consumption and fiber damage.

-

Inline sensors: conductivity, turbidity, moisture for real-time control.

-

Batch records & KPI tracking: keep logs of chemical use/kg, water L/kg, energy kWh/kg, and rework % to measure improvement.

19. Example batch recipes (illustrative — lab-trial before scale)

Assumptions: 100 kg cotton greige in a jet or jigger style batch line. Adjust proportionally.

-

Desize (enzymatic):

-

α-Amylase: 0.3 g/L (lab determine)

-

Non-ionic wetting agent: 1.0 g/L

-

Temp: 55 °C

-

Time: 45 min

-

Liquor ratio: 1:6

-

-

Rinse: 2 × 10 min cold/warm

-

Bleach (H₂O₂):

-

H₂O₂: 4.0 g/L

-

Sodium silicate (stabilizer/buffer): 1.5 g/L

-

Chelant (sequestering agent): 1.0 g/L

-

Alkali (if required to reach pH 10): adjust with soda ash carefully

-

Temp: 60–70 °C

-

Time: 20 min

-

-

Neutralize:

-

Acetic acid to pH 5.5

-

If residual peroxide detected → small dose sodium bisulfite per titration

-

-

Detergent wash:

-

Non-ionic detergent 2 g/L, 40–50 °C, 20 min

-

-

Rinse until conductivity/pH acceptable

-

Tinting (optional low shade reactive):

-

Reactive dye: 0.2–0.5% owf (on weight of fabric)

-

Salt (exhaust): 20–50 g/L depending on exhaust method

-

Temperature profile and alkali addition as per dye supplier (pad-batch or exhaust method)

-

-

Fixing (reactive):

-

Soda ash: to target pH 10–11

-

Hold 30–60 min at 40–60 °C

-

Soaping: hot detergent wash to remove hydrolyzed dye

-

-

Softener:

-

Silicone softener: 6–8 g/L, 30–40 °C, 10–15 min

-

-

Hydro & Dry: target residual moisture and dry to spec.

Important: These numbers are starting points. Always validate on a lab or pilot scale and consult chemical suppliers for exact dosing and compatibility.

20. Suggested SOP template (for a single batch)

-

Pre-check: fabric weight/GSM, machine status, chemicals & PPE.

-

Desize: load, set temp/pH/time, add enzyme at specified time, monitor.

-

Rinse: perform two rinses, check conductivity.

-

Bleach: prepare peroxide bath, add stabilizer/chelants, ramp temp, monitor peroxide residual.

-

Neutralize: slowly add acid to target pH, measure.

-

Clean/soaping: add detergent, maintain temp/time.

-

Rinse: measure final pH & conductivity.

-

Tinting: prepare dye bath, apply/pad, exhaust/fix as required.

-

Fixing: apply alkali or heat, hold, then soaping.

-

pH adjust: to final spec.

-

Softener: apply & rinse if required.

-

Hydro-extract & Dry.

-

QC: shade, whiteness, fastness, shrinkage tests.

-

Log all parameter readings in batch sheet.

Closing notes

This document provides a robust, practical blueprint of a wet-washing line using the steps you specified. The single most important themes for success are:

-

Know your substrate (fiber content, sizing type, prior finishes).

-

Control pH, temperature, and time precisely at every step.

-

Test on small scale before implementing full production changes.

-

Monitor effluent & operate within environmental laws; invest in ETP and water reuse where viable.

-

Keep detailed batch records for traceability and continual improvement.

-

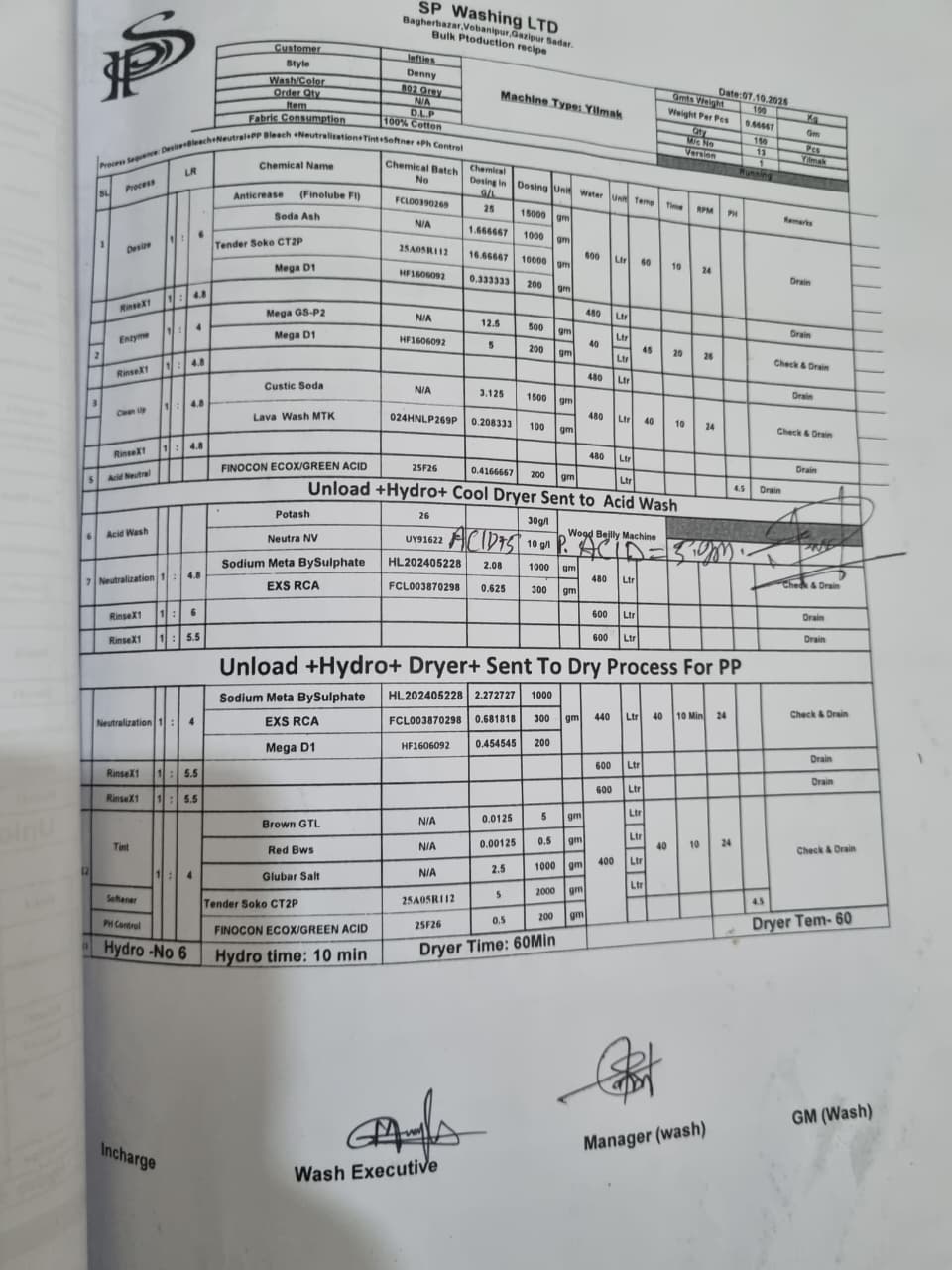

Wet Process Recipe For Bulk